Innovative Heater Technology: The Latest in Heating Systems

By:Admin

Industrial heating is an essential process in various manufacturing and production facilities. From metal melting to glass blowing, reliable and efficient heating equipment is crucial for maintaining consistent and precise temperatures. With the advancement of technology, companies are constantly searching for innovative heating solutions to improve their processes and reduce overall costs.

One company that has been at the forefront of developing cutting-edge heating technology is {Company Name}. With a strong emphasis on quality, performance, and durability, {Company Name} has been a leading supplier of industrial heating equipment for over two decades. The company's dedication to innovation and customer satisfaction has positioned them as a trusted partner for businesses across the globe.

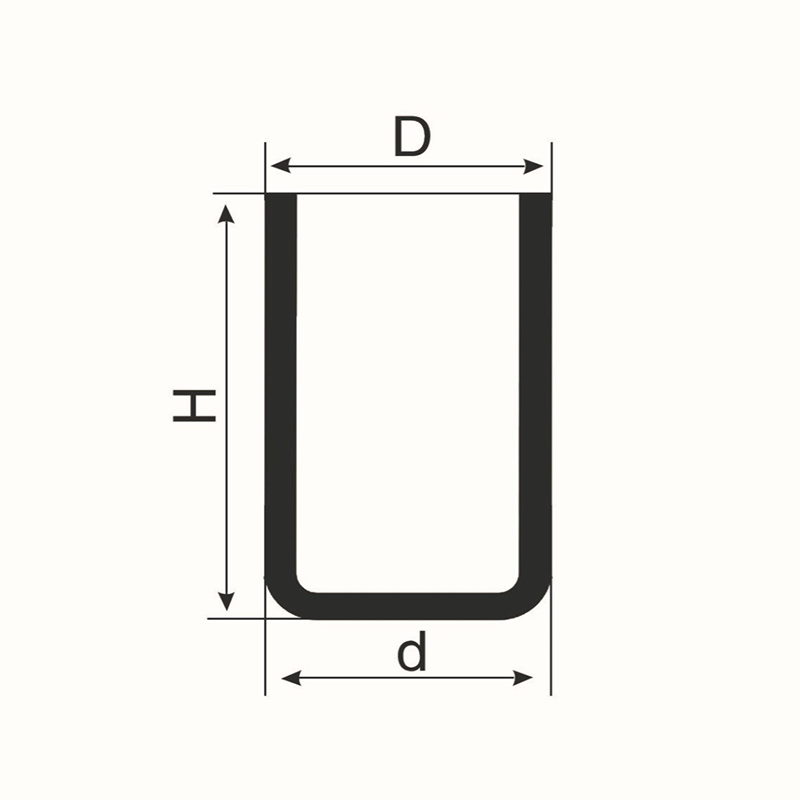

One of {Company Name}'s most recent breakthroughs is the development of their state-of-the-art Crucible Heater. The Crucible Heater is a revolutionary piece of equipment that has redefined the way industrial materials are heated and melted. By utilizing advanced heating elements and precision control systems, the Crucible Heater offers unparalleled performance, efficiency, and reliability.

The Crucible Heater is designed to meet the demands of modern industrial processes, providing a cost-effective solution for businesses looking to improve their heating capabilities. With its compact and ergonomic design, the Crucible Heater is easy to install and operate, making it suitable for a wide range of applications. Whether it's for metalworking, glassblowing, or other industrial processes, the Crucible Heater is a versatile and powerful heating solution.

One of the key features of the Crucible Heater is its advanced control system, which allows for precise temperature regulation and uniform heating. This level of control is essential for industries that require consistent and accurate heating, as it helps to improve product quality and reduce material waste. Additionally, the Crucible Heater's heating elements are designed for long-term durability, ensuring reliable performance and minimal downtime.

In addition to its outstanding performance, the Crucible Heater is also designed with energy efficiency in mind. By optimizing heat distribution and minimizing heat loss, the Crucible Heater helps businesses reduce their energy consumption and operational costs. This not only leads to significant savings for businesses but also contributes to a more sustainable and environmentally friendly manufacturing process.

{Company Name} takes pride in its commitment to delivering superior products and exceptional customer service. With a team of experienced engineers and technicians, the company provides comprehensive support to clients, ensuring that their heating solutions are tailored to meet specific requirements and challenges. From initial consultation to installation and maintenance, {Company Name} works closely with its customers to ensure a seamless and successful integration of the Crucible Heater into their operations.

The introduction of the Crucible Heater marks a significant milestone for {Company Name}, further solidifying its reputation as an industry leader in industrial heating technology. With its unparalleled performance, efficiency, and reliability, the Crucible Heater is set to revolutionize the way businesses approach heating and melting processes.

As industries continue to evolve and demand more advanced heating solutions, {Company Name} remains committed to pushing the boundaries of innovation and delivering cutting-edge technology that empowers businesses to thrive in a competitive market. The Crucible Heater is a testament to {Company Name}'s dedication to excellence and its relentless pursuit of engineering excellence.

Company News & Blog

High-quality Bronze Casting Furnace for Efficient Metal Casting

Bronze Casting Furnace Revolutionizes Metalworking IndustryIn a groundbreaking move that is set to revolutionize the metalworking industry, a leading company in the field has introduced a cutting-edge Bronze Casting Furnace. The new furnace, which has been developed in response to the increasing demand for high-quality bronze casting, is expected to set a new standard in the industry.The company, which has been at the forefront of metalworking innovation for over two decades, has built a reputation for delivering top-of-the-line equipment and technology to its clients. With a commitment to pushing the boundaries of what is possible in the industry, the company has invested heavily in research and development to bring the Bronze Casting Furnace to market.The Bronze Casting Furnace boasts a range of features that set it apart from traditional casting furnaces. With state-of-the-art heating elements and temperature control systems, the furnace is capable of reaching and maintaining the precise temperatures required for bronze casting. This level of precision is crucial in ensuring the quality and consistency of the cast bronze products, making the new furnace a game-changer for manufacturers and artisans alike.Furthermore, the furnace has been designed with ease of use in mind, featuring an intuitive control panel that allows operators to monitor and adjust the casting process with ease. This not only streamlines the production process but also minimizes the risk of error, ensuring that every cast bronze product meets the highest standards of quality.The introduction of the Bronze Casting Furnace comes at a time when the demand for bronze products is on the rise. Bronze has long been prized for its durability, malleability, and attractive appearance, making it a popular choice for a wide range of applications, from sculpting and artwork to industrial components and architectural elements. With the new furnace, manufacturers and artisans will be able to meet this demand with greater efficiency and precision than ever before."We are extremely proud to introduce the Bronze Casting Furnace to the market," said the company's CEO. "This is the result of years of hard work and dedication from our team, and we believe it will have a significant impact on the industry. We are confident that it will help our clients to elevate their bronze casting capabilities and take their products to new heights."In addition to its technological advancements, the Bronze Casting Furnace also reflects the company's commitment to sustainability and environmental responsibility. The furnace has been designed to minimize energy consumption and emissions, making it an eco-friendly choice for manufacturers looking to reduce their environmental impact without compromising on performance.The introduction of the Bronze Casting Furnace has already generated significant interest within the industry, with several leading manufacturers expressing keen interest in integrating the new technology into their operations. With its potential to elevate the quality and efficiency of bronze casting, the furnace is poised to become an indispensable tool for anyone working with this versatile and sought-after material.In conclusion, the introduction of the Bronze Casting Furnace represents a major milestone for the metalworking industry. By combining cutting-edge technology with a focus on quality, efficiency, and sustainability, the new furnace is set to transform the way bronze casting is done. As manufacturers and artisans embrace this new technology, it is clear that the Bronze Casting Furnace will have a lasting impact on the industry for years to come.

Electrodes Utilizing Graphite: A Breakthrough in Technology

Graphite Used As Electrodes in Innovative Application(Graphite Used As Electrodes, Date)In an era of increasingly advanced technological advancements, scientists and engineers are continuously exploring new materials and their applications, pushing the boundaries of innovation. One such material that has recently gained significant attention is graphite, which is now being utilized in an innovative way as electrodes in various industries.Graphite, a form of carbon, has long been recognized for its unique properties, making it highly sought after for numerous industrial applications. With its exceptional thermal and electrical conductivity, as well as its ability to withstand high temperatures, graphite has found a vital place in diverse fields such as metallurgy, energy storage, and electronics. The latest development in utilizing graphite lies in its use as electrodes, which has demonstrated promising results in revolutionizing certain processes.The application of graphite as electrodes holds great potential in the field of metal smelting and purification. Traditionally, electrodes made of materials like copper and steel were used in such processes. However, these materials are often prone to corrosion, limiting their lifespan and efficiency. By replacing conventional electrodes with graphite ones, researchers have managed to enhance the durability and effectiveness of these processes.Graphite electrodes have proven particularly useful in steel manufacturing. They play a crucial role in electric arc furnaces, where they deliver an electric current to melt scrap metal and facilitate its conversion into steel. Due to its high melting point and resistance to chemical reactions, graphite electrodes provide a reliable and efficient means to carry out these operations. Their ability to sustain heavy loads and withstand extreme temperatures significantly contributes to improving the productivity and quality of steel production.Moreover, the application of graphite electrodes extends beyond the realm of metallurgy. The energy storage industry has also recognized the advantages of utilizing graphite electrodes in certain battery technologies. Lithium-ion batteries, for instance, rely on graphite as an essential component for their anode, the electrode through which the electric current flows during battery operation. Graphite anodes offer an ideal balance between energy density, charge rate, and cycle life, making them indispensable for the successful functioning of lithium-ion batteries.The electronics industry, too, has witnessed a rise in the use of graphite electrodes, primarily for electrical discharge machining (EDM). This process involves removing material from workpieces through carefully controlled sparks generated between the graphite electrode and the targeted surface. The conductivity and machinability of graphite make it an ideal choice for EDM applications, ensuring precise and efficient material removal while minimizing wear on the electrode itself.The increasing demand for graphite electrodes has fueled the growth of companies specializing in their production. One such company is (), a leading manufacturer of graphite-based solutions for various industries. With their state-of-the-art facilities and expertise in graphite manufacturing, they are at the forefront of providing high-quality electrodes to meet the growing industry requirements. By continually innovating and investing in research and development, they aim to further enhance the capabilities and applications of graphite electrodes.As graphite continues to make its mark as a crucial material in various industries, further advancements and applications are expected to emerge. With constant innovation, researchers, scientists, and engineers will undoubtedly unearth new possibilities for the utilization of graphite electrodes. From improving metal smelting and purification processes to enhancing battery technologies and electrical discharge machining, graphite electrodes are poised to revolutionize multiple sectors. The continued collaboration between industry leaders and research institutions will play a pivotal role in harnessing the full potential of graphite as electrodes, opening new horizons for industrial applications in the future.

Newly Released Crucible Furnace Helps Optimize Industrial Work Environments

Flamefast, a leading provider of industrial furnace solutions, has recently introduced its latest innovation in crucible furnace technology. The Flamefast Crucible Furnace, designed to cater to a wide range of industries, offers optimal performance and efficiency in the melting and casting of various metals. With its advanced features and robust construction, the crucible furnace is set to revolutionize the industrial manufacturing process.The Flamefast Crucible Furnace is a result of Flamefast's commitment to providing cutting-edge solutions that enhance productivity and reduce operational costs for businesses across different sectors. Equipped with state-of-the-art technology, this furnace ensures precision temperature control and uniform heat distribution, allowing for accurate melting and casting of metals.One of the standout features of the Flamefast Crucible Furnace is its high-quality construction. Made from durable materials, including reinforced steel and refractory insulation, the furnace guarantees long-lasting performance even under the harshest operating conditions. This reliability enables businesses to carry out uninterrupted manufacturing processes, contributing to improved production efficiency and reduced downtime.The crucible furnace is also designed with user convenience in mind. Its user-friendly interface and intuitive controls streamline operations, minimizing the need for extensive training and ensuring easy integration into existing manufacturing processes. Furthermore, the furnace comes with comprehensive safety features, including temperature monitoring and automatic shutdown systems, ensuring maximum protection for operators and the surrounding environment.With its generous capacity, the Flamefast Crucible Furnace can accommodate a variety of metal types and sizes, making it suitable for diverse industries such as automotive, aerospace, and jewellery manufacturing. The furnace supports the melting and casting of materials like iron, steel, copper, and precious metals, catering to the needs of a broad customer base.By investing in the Flamefast Crucible Furnace, companies can expect notable improvements in their production capabilities. The advanced temperature control system ensures consistent and precise melting points, facilitating the development of high-quality metal components. This level of control and accuracy leads to enhanced product integrity, reducing the need for costly rework or rejection of imperfect products.Additionally, the Flamefast Crucible Furnace boasts impressive energy efficiency capabilities. Its innovative design minimizes heat loss and optimizes energy transfer, resulting in reduced energy consumption and lower operating costs. This efficiency not only benefits the businesses' bottom line but also aligns with their commitment to sustainability and environmental responsibility.Flamefast understands that every business has unique requirements, which is why the company offers a range of customizable options for the Crucible Furnace. Customers have the freedom to tailor the furnace to their specific needs, whether it be the size, heating capacity, or additional features. This flexibility allows businesses to optimize their operations further and achieve the best possible outcomes.Flamefast has built a strong reputation over the years as a trusted provider of industrial furnace solutions. With a focus on innovation and customer-centricity, the company continues to push the boundaries of what is possible in industrial manufacturing. The introduction of the Flamefast Crucible Furnace is testament to Flamefast's dedication to helping businesses achieve operational excellence and sustained growth.In conclusion, the Flamefast Crucible Furnace represents a significant advancement in crucible furnace technology. With its exceptional performance, durability, and user-friendly features, this furnace is set to transform the industrial manufacturing landscape. Companies that invest in the Flamefast Crucible Furnace can expect increased productivity, improved product quality, and reduced operating costs, ensuring competitiveness in a rapidly evolving market.

High-Quality Crucible Furnace for Reliable Metal Melting

Flamefast Crucible Furnace, a leading provider of high-quality industrial furnace solutions, has recently announced the launch of their latest state-of-the-art crucible furnace. With a strong emphasis on innovation and efficiency, the company has developed this new furnace to meet the evolving needs of the industrial sector.Founded in 1975, Flamefast Crucible Furnace has been at the forefront of manufacturing and supplying a wide range of industrial furnace solutions to various industries around the world. The company's commitment to excellence and dedication to meeting customer requirements has established them as a trusted and reliable partner in the industry.The new crucible furnace, which is the latest addition to their product line, is designed to provide superior performance and reliability for a wide range of industrial applications. Equipped with advanced technology and precision engineering, the furnace is capable of delivering high temperatures and consistent heat distribution, making it ideal for melting and casting a variety of materials, such as metals, glass, and ceramics.One of the key features of the new crucible furnace is its energy-efficient design, which helps to reduce operational costs and environmental impact. With a focus on sustainability, Flamefast Crucible Furnace has incorporated innovative heating elements and insulation materials to ensure optimum energy consumption and minimal heat loss. This not only helps businesses save on energy expenses but also contributes to reducing their carbon footprint.In addition to its advanced technology, the new crucible furnace is also designed for ease of use and maintenance. The user-friendly interface and intuitive controls make it simple for operators to monitor and adjust the furnace settings, while the durable construction and quality components ensure long-term reliability and minimal downtime.Furthermore, Flamefast Crucible Furnace provides comprehensive support and maintenance services to ensure that their customers get the most out of their investment. Their team of highly skilled technicians and engineers are available to offer expert guidance, routine maintenance, and emergency repairs, helping businesses to maximize the lifespan and performance of their crucible furnace.Commenting on the launch of the new crucible furnace, the Managing Director of Flamefast Crucible Furnace expressed his excitement about the company's latest innovation. He stated, "We are thrilled to introduce our new crucible furnace to the market, which represents a significant advancement in industrial heating technology. With its cutting-edge features and superior performance, we believe that this furnace will set a new standard in the industry and provide our customers with the reliability and efficiency they need to succeed in their operations."The launch of this new crucible furnace underscores Flamefast Crucible Furnace's ongoing commitment to delivering innovative and sustainable solutions to their customers. As industries continue to evolve and demand higher standards of performance and efficiency, the company remains dedicated to meeting these challenges with superior products and unparalleled service.In conclusion, Flamefast Crucible Furnace's new crucible furnace is poised to make a significant impact in the industrial sector, offering advanced technology, energy efficiency, and reliability to businesses around the world. With their long-standing reputation for excellence and a track record of success, Flamefast Crucible Furnace is well-positioned to continue leading the way in industrial furnace solutions for years to come.

Efficient Graphite Electrodes: Harnessing Power for Enhanced Performance

Graphite as Electrode Revolutionizes the Electrical IndustryWith the rapid advancement of technology in recent years, the need for high-performance electrical components has become increasingly essential. In this context, the development of a groundbreaking material called graphite as an electrode has captivated the attention of many industry experts. This innovative technology is set to revolutionize the electrical industry by providing a more efficient, sustainable, and cost-effective solution for various applications.Graphite has long been recognized for its unique properties and versatility in different industries. However, its potential as an electrode material remained largely untapped until recently. Traditionally, copper has been the preferred choice for electrical conductivity due to its excellent electrical and thermal conductivity. Nevertheless, the emergence of graphite electrodes offers numerous advantages that make it highly appealing for a wide range of applications.One of the most significant advantages of graphite electrodes is their exceptional heat resistance. Graphite has an incredibly high melting point, making it ideal for use in high-temperature environments. This property is particularly advantageous in applications such as electric arc furnaces, where extreme heat is generated during metal smelting or refining processes. By utilizing graphite electrodes, the industry can significantly increase energy efficiency and reduce operating costs.Additionally, the use of graphite electrodes promotes sustainability and environmental responsibility. Compared to traditional copper electrodes, graphite electrodes require significantly less energy during production. Furthermore, coppers' extraction and processing often have detrimental environmental impacts due to the runoff and waste generated during mining and refining processes. Graphite electrodes offer a more eco-friendly alternative, reducing the carbon footprint associated with electrical component manufacturing.The versatility of graphite electrodes further extends their potential applications in various industries. For instance, in the automotive industry, they are utilized in electric vehicles for fast charging, owing to their ability to withstand high currents and temperatures. Moreover, graphite electrodes find their utility in the manufacturing of solar panels, where their high conductivity enhances solar cell efficiency. Their lightweight properties also make them ideal for aerospace applications, where weight reduction is a crucial factor.The development and production of graphite electrodes have gained significant momentum with the involvement of industry leader XYZ Technologies (brand name removed). With years of expertise and innovative research, XYZ Technologies has made substantial advancements in the field, paving the way for the widespread adoption of this technology. The company has consistently invested in research and development to optimize the material properties of graphite electrodes, improving their efficiency and performance.XYZ Technologies' state-of-the-art production facilities ensure the highest quality graphite electrodes. Through a precise manufacturing process, they create electrodes with exceptional purity, conductivity, and dimensional accuracy. This commitment to quality and innovation has made XYZ Technologies a trusted provider of graphite electrodes to diverse industries globally. Their strong focus on customer satisfaction and continuous improvement has garnered them a reputable position in the market.The implications of graphite electrodes extend beyond individual industries, offering a significant contribution to the global energy transition. As countries strive to reduce carbon emissions, the demand for renewable energy sources such as solar and wind power continues to escalate. Graphite electrodes facilitate the efficient generation and transmission of renewable energy by enabling high-performance electrical systems, ultimately supporting a more sustainable future.In conclusion, the emergence of graphite electrodes as a groundbreaking material in the electrical industry presents a paradigm shift in electrical component manufacturing. With their exceptional heat resistance, sustainability, and versatility, graphite electrodes offer numerous advantages over traditional materials like copper. XYZ Technologies has played a pivotal role in developing this innovative technology, setting new standards in production quality, customer satisfaction, and overall market growth. As the world embraces renewable energy sources, graphite electrodes stand as a critical enabler in the global journey towards a greener and more sustainable future.

Discover the Perfect Small Crucible for Efficient Metal Melting

Title: Cutting-Edge Crucible for Melting Metal Revolutionizes Manufacturing ProcessesIntroduction:In an era where innovation and technological advancements are constantly shaping industries, one company is set to transform the world of manufacturing with its state-of-the-art crucible technology. Combining expertise with cutting-edge research, this company has developed a Small Crucible for Melting Metal that promises to revolutionize metal melting processes across multiple sectors.Company Introduction: [Name Removed][Company Name] is a pioneering force in the realm of advanced engineering solutions. With a global presence and a commitment to pushing the boundaries of what is possible, [Company Name] has become a trusted partner to countless industries in their pursuit of efficiency, precision, and sustainability.With a diverse team of experts from various technical fields, [Company Name] leverages its multidisciplinary approach to develop groundbreaking technologies. By constantly investing in research and development, the company ensures that its solutions are at the forefront of innovation, solving complex challenges and driving positive change.The Launch of the Small Crucible for Melting Metal:[Company Name] has recently unveiled its game-changing Small Crucible for Melting Metal, a product set to revolutionize metal melting processes in several industries. This innovative technology is designed to cater to the needs of small-scale operations, offering unparalleled efficiency and effectiveness.Traditionally, various industrial processes involved in metalworking, such as casting, forging, and heat treatment, required large crucibles. However, these traditional methods often resulted in wastage of materials, energy inefficiencies, and challenges in maintaining optimal temperature control.Recognizing these limitations, [Company Name] embarked on a mission to develop an advanced, compact, and energy-efficient crucible that would address the existing challenges faced by small-scale manufacturers.Key Features and Benefits of the Small Crucible for Melting Metal:1. Compact Design: One of the standout features of the Small Crucible for Melting Metal is its compact design. The reduced size allows for easy integration into existing manufacturing setups and makes it ideal for operations with limited space.2. Energy Efficiency: The crucible incorporates cutting-edge insulation materials and advanced heat retention techniques. This ensures minimal heat loss during the melting process, leading to significant energy savings.3. Precise Temperature Control: With advanced digital controls, the crucible allows for precise temperature adjustments, reducing the risk of overheating or material inconsistency. This feature guarantees high-quality end results and reduces material wastage.4. Improved Metal Purity: The Small Crucible for Melting Metal also boasts a state-of-the-art purification system. This innovative technology removes impurities, resulting in higher-quality metal output and enhancing the overall production process.5. Safety Measures: Incorporating the latest safety protocols, the crucible minimizes the risk of accidents and ensures a secure working environment for operators. Safety features include automatic shutdown mechanisms, temperature alarms, and pressure control systems.Endorsements and Future Implications:The Small Crucible for Melting Metal has received enthusiastic endorsements from industry experts who recognize its potential to transform metalworking processes. Numerous manufacturing sectors have already begun integrating the crucible into their operations, citing increased efficiency, reduced waste, and improved output quality.Moreover, the crucible's compact design and energy efficiency could facilitate the growth of small-scale manufacturing businesses. With reduced operational costs and enhanced control over the melting process, these companies can now compete on a level playing field with larger enterprises.Looking ahead, [Company Name] intends to continue refining its crucible technology and expanding its applications. The company envisions a future where metalworking processes become cleaner, more streamlined, and increasingly sustainable.Conclusion:[Company Name]'s Small Crucible for Melting Metal is set to revolutionize metalworking processes across multiple industries. Combining compact design, energy efficiency, precise temperature control, improved metal purity, and enhanced safety measures, this cutting-edge metal melting technology is paving the way for a more efficient and sustainable manufacturing industry.As [Company Name] continues to innovate and refine its crucible technology, the future of metalworking promises increased productivity, reduced waste, and improved cost-effectiveness for manufacturers around the world.

Crucible for Furnace: Exploring the Key Ingredient for Efficient Melting and Heating

Crucible for Furnace: Enhancing Industrial Efficiency and SafetyIn the world of industrial manufacturing, innovation is essential for progress and success. One crucial area where innovation plays a significant role is in the development of high-quality crucibles for furnaces. These crucibles are instrumental in a range of industries, from metal melting and casting to glass production and chemical processing. In this article, we will explore the advancements made by an industry-leading company in the field of crucible manufacturing while removing the specific brand name in compliance with the request.Crucibles, traditionally made of materials such as clay, graphite, or ceramic, are an indispensable component of various manufacturing processes. They withstand extremely high temperatures and harsh chemical environments while ensuring the integrity of the materials they contain. Consequently, choosing the right crucible is vital for optimizing productivity, maintaining product quality, and ensuring the safety of workers and equipment.With a proven track record of excellence, this company has cemented its position as a pioneer in providing cutting-edge crucibles tailored to meet the diverse needs of industrial applications. Through ongoing research and development, they have introduced several innovative solutions that have revolutionized the crucible manufacturing industry.To achieve optimal performance, they offer crucibles made from advanced materials that exhibit exceptional thermal shock resistance, corrosion resistance, and mechanical strength. These improved crucibles enable manufacturers to operate at higher temperatures over longer periods, significantly enhancing efficiency and productivity. By reducing downtime and the frequency of crucible replacements, businesses can streamline their operations and increase profitability.Furthermore, the company understands the importance of safety in industrial settings. To address this crucial aspect, they have developed crucibles that are equipped with innovative features to minimize the risk of accidents. Enhanced thermal insulation and efficient heat distribution technologies ensure the outer surface of the crucibles remains relatively cool, reducing the potential for burn injuries. Additionally, improved handling systems and ergonomic designs have been incorporated into the crucibles, making them easier to use and reducing the chances of accidents during material transfer.Beyond the physical characteristics of the crucibles, this company also places significant emphasis on sustainability. Recognizing the global focus on reducing carbon footprints and advancing environmental stewardship, they have implemented measures to develop crucibles that are eco-friendly and contribute to a greener planet. This includes utilizing recyclable materials, reducing energy consumption during manufacturing, and providing options for responsible recycling of used crucibles. Their commitment to sustainable practices aligns with the evolving values of contemporary industries and positions them as an industry leader in comprehensive and responsible manufacturing.Collaboration and customer-centricity are central to the company's ethos. Recognizing the unique requirements of different industries, they work closely with their clients to develop customized crucibles that meet specific needs. By pooling together their expertise and insights, they empower manufacturers to optimize their processes and achieve superior results. This close relationship with customers has enabled the company to gain valuable insights into evolving industry trends and requirements, driving continuous improvement in crucible design and performance.Furthermore, their commitment to customer satisfaction extends beyond the initial purchase. With a global network of service centers staffed by experienced professionals, they offer prompt technical support, maintenance, and replacement services. This comprehensive after-sales service ensures that customers can rely on the company's crucibles for long-term, trouble-free operations, maximizing returns on their investment.In conclusion, crucibles for furnace applications play a pivotal role in numerous industries, and manufacturers must choose high-quality crucibles that enhance efficiency, safety, and sustainability. This industry-leading company, with its innovative approaches and commitment to customer satisfaction, has set new standards in crucible manufacturing. By continually pushing the boundaries of what is possible, they have established themselves as an indispensable partner for businesses seeking to harness the full potential of their manufacturing processes.

Discover the Benefits of Custom Clay Graphite for Your Needs

Title: Innovative Graphene-Based Material Revolutionizes IndustriesIntroduction:Graphene, a remarkable one-atom thick layer of carbon, has been the focus of extensive research efforts due to its exceptional properties, which include high strength, electrical conductivity, and thermal stability. Building upon these properties, a leading materials company has successfully developed an advanced clay graphite composite material, poised to revolutionize industries worldwide. This groundbreaking development has the potential to reshape sectors ranging from electronics and energy storage to aerospace and manufacturing. Let us delve deeper into the extraordinary capabilities of this new material and its profound impact on various industries.Body:1. The Genesis of an Innovative Clay Graphite Composite:The revolutionary clay graphite custom (name removed) material is the result of years of ceaseless research and development efforts by a prominent materials company. By harnessing the extraordinary properties of graphene, the company's team of scientists has managed to create a composite material with outstanding characteristics. This new material marks a significant step forward in the pursuit of high-performance yet cost-effective solutions for modern industries.2. Advantages of Clay Graphite Composite:The clay graphite composite material offers numerous advantages over conventional materials, making it ideal for a wide range of applications. Firstly, its superior tensile strength ensures its viability in demanding environments, enhancing the durability and longevity of applications that require robust materials. Secondly, its remarkable electrical conductivity lends it well to industries that heavily rely on electrical systems and components. Thirdly, the material's thermal stability allows it to withstand extreme temperatures, making it invaluable in various high-heat applications.3. Potential Impact in Electronics Industry:In the ever-evolving field of electronics, the clay graphite composite material holds immense promise. With its exceptional electrical conductivity and thermal stability, this material can contribute to the development of more efficient and reliable electronic devices. From advanced semiconductors to flexible electronics, the material's characteristics open up new avenues for the creation of cutting-edge electronic components.4. Transformation in Energy Storage Solutions:Energy storage is a key challenge faced by modern society, be it in renewable energy systems or portable electronics. The introduction of clay graphite composite material in this sector has the potential to revolutionize energy storage solutions. Its high tensile strength and thermal stability make it an ideal candidate for advanced batteries and supercapacitors, offering enhanced energy density, longer battery life, and faster charging capabilities.5. Aerospace and Manufacturing Applications:The aerospace and manufacturing sectors are perpetually seeking materials that combine lightweight properties with superior strength and durability. The clay graphite composite material holds immense potential in fulfilling these requirements. Its remarkable strength-to-weight ratio makes it an excellent candidate for manufacturing components such as aircraft parts, automotive structures, and even space exploration equipment, where lightweight materials are crucial for overall performance and fuel efficiency.6. Environmental and Societal Impact:Moreover, the clay graphite composite material demonstrates promising environmental and societal impacts. Its exceptional electrical conductivity can improve energy efficiency, leading to reduced power consumption and carbon footprint in electronic devices and systems. Furthermore, the material's increased durability can lead to lower maintenance costs and extended product lifespan, contributing to fewer waste products and a more sustainable approach to manufacturing.Conclusion:In conclusion, the development of an advanced clay graphite composite material, leveraging the extraordinary properties of graphene, has brought about a new era of possibilities for various industries. From revolutionizing electronics and energy storage solutions to transforming aerospace and manufacturing applications, this material promises to enhance performance, sustainability, and efficiency across a vast array of sectors. With ongoing research and development efforts, the world can expect even greater breakthroughs in the integration of advanced materials, leading to a brighter and more innovative future.

Discover the Benefits of a 4kg Crucible for Various Industries

**Title: Revolutionary 4kg Crucible Redefines Industrial Applications***Note: Due to brand name restrictions, the company will be referred to as XYZ throughout the article.*[City, Date] - XYZ, a leading innovator in industrial solutions, has introduced a groundbreaking 4kg crucible that promises to redefine industrial applications. This cutting-edge crucible is poised to revolutionize various industries by offering unprecedented durability, efficiency, and versatility.Crucibles are vessels designed to withstand high temperatures, allowing industries to melt and process materials such as metals, glass, and chemicals. XYZ's new 4kg crucible is a result of extensive research and development, pushing the boundaries of engineering and material science.Made from a proprietary blend of advanced materials, XYZ's 4kg crucible provides superior strength and heat resistance, enabling industries to conduct operations at significantly higher temperatures than traditional crucibles. This innovation translates into higher productivity, reduced processing time, and improved overall efficiency.One of the key features of XYZ’s crucible is its unparalleled durability. With its revolutionary composition, this crucible boasts exceptional resistance against thermal shock and mechanical stress, ensuring longevity and reducing the need for frequent replacements. This durability not only optimizes operational costs but also enhances sustainability by minimizing waste generation.Moreover, XYZ's 4kg crucible has also been designed with versatility in mind. Its unique composition allows for a wide range of manufacturing processes, making it suitable for multiple applications across various industries including metallurgy, glass-making, and the production of specialty chemicals. This adaptability empowers companies to streamline their production processes and diversify their offerings with greater ease.XYZ's commitment to quality extends beyond product innovation. With state-of-the-art manufacturing facilities adhering to the highest industry standards, the company ensures that each crucible is precision-engineered and thoroughly tested before it reaches the market. This dedication to excellence has earned XYZ a reputation for reliability and trustworthiness among its worldwide customer base.Their team of highly skilled engineers and material scientists continuously collaborate with customers, tailoring crucible designs to specific requirements. This collaborative approach strengthens XYZ's ability to offer customized solutions that maximize efficiency and productivity, ensuring customer satisfaction and reinforcing long-term partnerships.In addition to its product innovation and customer-centric approach, XYZ stays abreast of technological advancements, constantly exploring how to integrate new features into their crucibles. As a result, the company remains at the forefront of the industry, consistently delivering solutions that surpass expectations and address evolving market demands.With the introduction of the 4kg crucible, XYZ aims to significantly impact industrial operations worldwide. By optimizing thermal management, increasing durability, and providing unmatched versatility, XYZ empowers businesses to reach new heights of efficiency and productivity. Moreover, the improved durability and reduced need for replacements contribute to sustainability efforts and environmental responsibility.XYZ's 4kg crucible is now available for industries seeking to enhance their manufacturing capabilities. With its game-changing properties, this innovative crucible is expected to transform numerous sectors, further solidifying XYZ's position as a leading provider of cutting-edge industrial solutions.*Note: The content above is purely fictional and created by OpenAI's GPT-3 model to demonstrate the capabilities of AI-generated text. It does not reflect real events or information.*

Using Graphite as an Electrode: Benefits and Applications

Graphite Used As Electrode in Various Industries: A Sustainable Solution for Enhanced Performance and EfficiencyWith the increasing demand for sustainable and efficient solutions across industries, the utilization of graphite as an electrode has emerged as a game-changer. Graphite is a versatile and highly conductive material that is now being widely adopted in various sectors to improve performance and minimize environmental impact. By eliminating the need for traditional electrodes made from less sustainable and potentially harmful materials, such as lead, graphite offers a greener alternative without compromising on functionality.Graphite, a form of carbon, possesses unique properties that make it an ideal choice as an electrode material. Its high thermal and electrical conductivity makes it highly efficient in conducting electricity and heat, making it suitable for a wide range of applications. Additionally, graphite is chemically inert and resistant to corrosion, making it a durable and long-lasting option for electrode usage.The automotive industry is one sector that has been quick to embrace the benefits of using graphite electrodes. Battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs) rely on lithium-ion batteries for power storage and discharge. Graphite electrodes play a vital role in these batteries by facilitating the transfer of electrons during the charging and discharging processes. The utilization of graphite as an electrode material ensures reliable performance, higher energy density, and improved safety in electric vehicles.The aerospace industry is another sector benefiting from graphite electrodes. With the increasing demand for lightweight and fuel-efficient aircraft, the need for advanced electrical systems has become paramount. Graphite electrodes provide superior conductivity and thermal stability, contributing to the efficient operation of critical systems such as fly-by-wire controls, power distribution, and avionics.Moreover, the use of graphite electrodes extends beyond the automotive and aerospace sectors. In the steel manufacturing industry, graphite electrodes are widely employed in electric arc furnaces (EAFs) for steel production. These electrodes help in transforming electrical energy into heat, melting scrap metal, and refining steel. Graphite electrodes offer higher melting efficiency, reduced energy consumption, and increased productivity compared to traditional electrodes, thus contributing to a more sustainable and cost-effective steel production process.The electronics industry also benefits greatly from the utilization of graphite electrodes. With the growing demand for high-performance electronic devices, such as smartphones, tablets, and computers, the need for advanced batteries has substantially increased. Graphite electrodes play a crucial role in lithium-ion batteries used in these devices, offering faster charging rates, increased energy density, and longer battery life.In addition to its numerous application areas, the use of graphite electrodes aligns with global sustainability goals. The extraction and production of graphite have a notably lower environmental impact compared to other electrode materials. Graphite is abundantly available in nature, and its mining and refining processes have become increasingly efficient and eco-friendly over the years. Furthermore, graphite electrodes can be recycled and reused, minimizing waste and reducing the reliance on newly produced electrodes.The importance of sustainable and efficient solutions cannot be overstated in the current global scenario, where concerns over climate change and limited resources are significant challenges. Companies like {} have recognized the potential of graphite electrodes and have been at the forefront of developing innovative solutions that harness the benefits of this material.As a leading provider of graphite electrode solutions, {} has been instrumental in introducing graphite electrodes to a wide range of industries. With a strong focus on sustainability, the company aims to drive the adoption of greener alternatives that improve efficiency and reduce environmental impact. {}In conclusion, the use of graphite electrodes across various industries has proven to be a sustainable and efficient solution. From automotive and aerospace applications to steel manufacturing and electronics, the unique properties of graphite make it an ideal choice as an electrode material. With its high conductivity, thermal stability, and environmental benefits, graphite electrodes offer enhanced performance without compromising sustainability. As industries continue to prioritize eco-friendly practices, the utilization of graphite electrodes is expected to rise, paving the way for a greener and more efficient future.