Unveiling the Intense Heat of a 3000 Degree Crucible: A Glimpse into Extreme Temperatures

By:Admin

Introduction:

In a groundbreaking development, a cutting-edge crucible with a mind-boggling capacity to endure extreme temperatures has been introduced to revolutionize industrial processes. Undoubtedly, this innovative technology is set to redefine manufacturing and refining operations by withstanding temperatures up to an astonishing 3000 degrees, offering unparalleled potential for various industries. Developed by a pioneering company dedicated to pushing the boundaries of industrial innovations, the 3000 Degree Crucible promises to enhance efficiency and productivity across multiple sectors while ensuring utmost safety.

Body:

1. Overview of Crucible Technology:

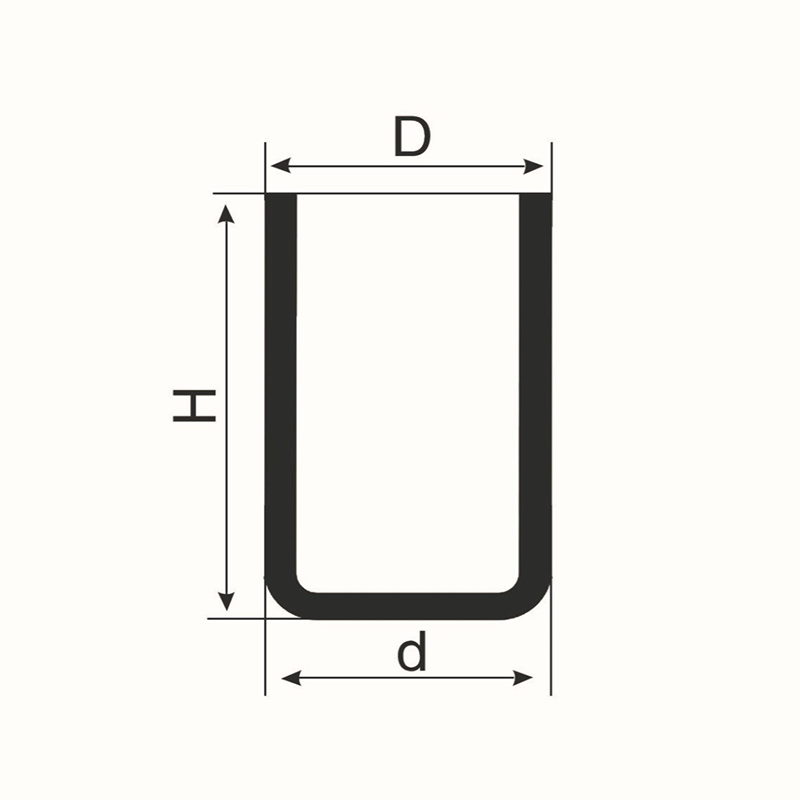

The 3000 Degree Crucible, designed and manufactured by [Company Name], is a game-changer in the field of industrial materials and equipment. This exceptional crucible is constructed using advanced composite materials, ensuring its ability to withstand incredibly high temperatures without compromising performance.

2. Applications and Benefits:

The applications of the 3000 Degree Crucible are limitless. With its remarkable heat resistance, industries such as metal casting, glass manufacturing, superalloy production, and chemical refining can benefit immensely. By withstanding temperatures typically unachievable by traditional crucibles, this revolutionary technology enables companies to push the boundaries of their manufacturing processes, amplifying efficiency, and reducing operational costs.

Moreover, the superior heat resistance of the crucible aligns with the growing demand for more sustainable and environmentally friendly practices. By allowing industries to operate at higher temperatures, the need for reheating and frequent replacements is diminished, resulting in significant energy and resource savings.

3. Enhanced Durability and Safety:

The 3000 Degree Crucible holds a significant advantage by offering an unparalleled level of durability and safety. Companies across industries have often faced challenges in maintaining crucibles that can handle extreme heat conditions. However, this novel technology eliminates such concerns due to its exemplary thermal stability, ensuring prolonged use without compromising production quality. By significantly reducing the frequency of replacement, businesses can save both time and costs associated with frequent maintenance and equipment downtime.

Furthermore, the enhanced safety features of the 3000 Degree Crucible are paramount in high-risk industrial environments. The crucible's exceptional heat resistance capability minimizes the risks of accidental melting, cracking, or leaking associated with conventional crucibles, consequently reducing the possibility of accidents and hazardous incidents.

4. Market Impact and Future Prospects:

The introduction of the 3000 Degree Crucible has already created ripples in the industrial landscape. Companies that have successfully integrated this innovative technology report increased production output, improved product quality, and reduced operating expenses. The versatile applications and benefits of the 3000 Degree Crucible ensure its potential to become an industry standard across various sectors.

Moreover, the durability, safety, and sustainability aspects of this technology are expected to attract significant attention and investment within the industrial sector. This increased interest will spur further research and development aimed at improving the crucible's capabilities, potentially surpassing the already impressive 3000 degree threshold.

Conclusion:

In conclusion, the introduction of the 3000 Degree Crucible marks a significant milestone in the world of industrial processes. By withstanding extreme temperatures that were once considered impossible, this revolutionary technology promises to transform multiple industries across the globe. The crucible's exceptional heat resistance, enhanced durability, and improved safety features are set to redefine manufacturing and refining operations. As the industrial sector continues to prioritize efficiency and sustainability, the 3000 Degree Crucible by [Company Name] paves the way for a future filled with safer, more sustainable, and technologically advanced industrial processes.

Company News & Blog

Electrodes Utilizing Graphite: A Breakthrough in Technology

Graphite Used As Electrodes in Innovative Application(Graphite Used As Electrodes, Date)In an era of increasingly advanced technological advancements, scientists and engineers are continuously exploring new materials and their applications, pushing the boundaries of innovation. One such material that has recently gained significant attention is graphite, which is now being utilized in an innovative way as electrodes in various industries.Graphite, a form of carbon, has long been recognized for its unique properties, making it highly sought after for numerous industrial applications. With its exceptional thermal and electrical conductivity, as well as its ability to withstand high temperatures, graphite has found a vital place in diverse fields such as metallurgy, energy storage, and electronics. The latest development in utilizing graphite lies in its use as electrodes, which has demonstrated promising results in revolutionizing certain processes.The application of graphite as electrodes holds great potential in the field of metal smelting and purification. Traditionally, electrodes made of materials like copper and steel were used in such processes. However, these materials are often prone to corrosion, limiting their lifespan and efficiency. By replacing conventional electrodes with graphite ones, researchers have managed to enhance the durability and effectiveness of these processes.Graphite electrodes have proven particularly useful in steel manufacturing. They play a crucial role in electric arc furnaces, where they deliver an electric current to melt scrap metal and facilitate its conversion into steel. Due to its high melting point and resistance to chemical reactions, graphite electrodes provide a reliable and efficient means to carry out these operations. Their ability to sustain heavy loads and withstand extreme temperatures significantly contributes to improving the productivity and quality of steel production.Moreover, the application of graphite electrodes extends beyond the realm of metallurgy. The energy storage industry has also recognized the advantages of utilizing graphite electrodes in certain battery technologies. Lithium-ion batteries, for instance, rely on graphite as an essential component for their anode, the electrode through which the electric current flows during battery operation. Graphite anodes offer an ideal balance between energy density, charge rate, and cycle life, making them indispensable for the successful functioning of lithium-ion batteries.The electronics industry, too, has witnessed a rise in the use of graphite electrodes, primarily for electrical discharge machining (EDM). This process involves removing material from workpieces through carefully controlled sparks generated between the graphite electrode and the targeted surface. The conductivity and machinability of graphite make it an ideal choice for EDM applications, ensuring precise and efficient material removal while minimizing wear on the electrode itself.The increasing demand for graphite electrodes has fueled the growth of companies specializing in their production. One such company is (), a leading manufacturer of graphite-based solutions for various industries. With their state-of-the-art facilities and expertise in graphite manufacturing, they are at the forefront of providing high-quality electrodes to meet the growing industry requirements. By continually innovating and investing in research and development, they aim to further enhance the capabilities and applications of graphite electrodes.As graphite continues to make its mark as a crucial material in various industries, further advancements and applications are expected to emerge. With constant innovation, researchers, scientists, and engineers will undoubtedly unearth new possibilities for the utilization of graphite electrodes. From improving metal smelting and purification processes to enhancing battery technologies and electrical discharge machining, graphite electrodes are poised to revolutionize multiple sectors. The continued collaboration between industry leaders and research institutions will play a pivotal role in harnessing the full potential of graphite as electrodes, opening new horizons for industrial applications in the future.

Discover the Perfect Small Crucible for Efficient Metal Melting

Title: Cutting-Edge Crucible for Melting Metal Revolutionizes Manufacturing ProcessesIntroduction:In an era where innovation and technological advancements are constantly shaping industries, one company is set to transform the world of manufacturing with its state-of-the-art crucible technology. Combining expertise with cutting-edge research, this company has developed a Small Crucible for Melting Metal that promises to revolutionize metal melting processes across multiple sectors.Company Introduction: [Name Removed][Company Name] is a pioneering force in the realm of advanced engineering solutions. With a global presence and a commitment to pushing the boundaries of what is possible, [Company Name] has become a trusted partner to countless industries in their pursuit of efficiency, precision, and sustainability.With a diverse team of experts from various technical fields, [Company Name] leverages its multidisciplinary approach to develop groundbreaking technologies. By constantly investing in research and development, the company ensures that its solutions are at the forefront of innovation, solving complex challenges and driving positive change.The Launch of the Small Crucible for Melting Metal:[Company Name] has recently unveiled its game-changing Small Crucible for Melting Metal, a product set to revolutionize metal melting processes in several industries. This innovative technology is designed to cater to the needs of small-scale operations, offering unparalleled efficiency and effectiveness.Traditionally, various industrial processes involved in metalworking, such as casting, forging, and heat treatment, required large crucibles. However, these traditional methods often resulted in wastage of materials, energy inefficiencies, and challenges in maintaining optimal temperature control.Recognizing these limitations, [Company Name] embarked on a mission to develop an advanced, compact, and energy-efficient crucible that would address the existing challenges faced by small-scale manufacturers.Key Features and Benefits of the Small Crucible for Melting Metal:1. Compact Design: One of the standout features of the Small Crucible for Melting Metal is its compact design. The reduced size allows for easy integration into existing manufacturing setups and makes it ideal for operations with limited space.2. Energy Efficiency: The crucible incorporates cutting-edge insulation materials and advanced heat retention techniques. This ensures minimal heat loss during the melting process, leading to significant energy savings.3. Precise Temperature Control: With advanced digital controls, the crucible allows for precise temperature adjustments, reducing the risk of overheating or material inconsistency. This feature guarantees high-quality end results and reduces material wastage.4. Improved Metal Purity: The Small Crucible for Melting Metal also boasts a state-of-the-art purification system. This innovative technology removes impurities, resulting in higher-quality metal output and enhancing the overall production process.5. Safety Measures: Incorporating the latest safety protocols, the crucible minimizes the risk of accidents and ensures a secure working environment for operators. Safety features include automatic shutdown mechanisms, temperature alarms, and pressure control systems.Endorsements and Future Implications:The Small Crucible for Melting Metal has received enthusiastic endorsements from industry experts who recognize its potential to transform metalworking processes. Numerous manufacturing sectors have already begun integrating the crucible into their operations, citing increased efficiency, reduced waste, and improved output quality.Moreover, the crucible's compact design and energy efficiency could facilitate the growth of small-scale manufacturing businesses. With reduced operational costs and enhanced control over the melting process, these companies can now compete on a level playing field with larger enterprises.Looking ahead, [Company Name] intends to continue refining its crucible technology and expanding its applications. The company envisions a future where metalworking processes become cleaner, more streamlined, and increasingly sustainable.Conclusion:[Company Name]'s Small Crucible for Melting Metal is set to revolutionize metalworking processes across multiple industries. Combining compact design, energy efficiency, precise temperature control, improved metal purity, and enhanced safety measures, this cutting-edge metal melting technology is paving the way for a more efficient and sustainable manufacturing industry.As [Company Name] continues to innovate and refine its crucible technology, the future of metalworking promises increased productivity, reduced waste, and improved cost-effectiveness for manufacturers around the world.

The Latest Advancements in High-Quality Graphite Crucibles for Silicon Processing

Title: Revolutionary Silicon Graphite Crucibles Enhance Industrial EfficiencyIntroduction:In a groundbreaking development that promises to revolutionize industrial processes, a leading materials manufacturer has introduced an innovative Silicon Graphite Crucible. Developed through extensive research and cutting-edge technology, this disruptive crucible is set to transform the manufacturing landscape by boosting efficiency and durability. By seamlessly combining the superior thermal properties of graphite with the enhanced strength and resistance of silicon, this crucible is poised to become an essential tool for various industrial applications.Paragraph 1:Silicon Graphite Crucibles are widely recognized as a critical component in numerous high-temperature industrial processes such as metal melting, casting, and refining. With the aim of addressing longstanding constraints and optimizing performance, {Company Name} has introduced their latest crucible which has garnered tremendous attention within the manufacturing industry. The new crucible boasts exceptional thermal conductivity, efficient heat distribution, and remarkable resistance to thermal shock, thereby providing an unparalleled solution for industries seeking to enhance their operating efficiency.Paragraph 2:The high thermal conductivity of Silicon Graphite Crucibles ensures efficient heat transfer during various melting operations. With this innovative crucible, industrial processes can achieve rapid temperature rises and precise heat control, leading to reduced energy consumption and shorter processing times. Heat distribution across the molten material is optimized, guaranteeing uniformity and minimizing heat-related defects. These characteristics result in higher productivity and superior product quality, positioning {Company Name}'s Silicon Graphite Crucibles as a game-changer in the manufacturing domain.Paragraph 3:The incorporation of silicon in the crucible's composition significantly strengthens its mechanical properties, making it highly resistant to cracking, breaking, and wear. This elevated durability translates into extended crucible life cycles, reducing downtime and overall costs for industrial operations. Moreover, the crucible's enhanced resistance to thermal shock allows it to withstand rapid temperature fluctuations without compromising its integrity. This attribute is particularly beneficial for applications involving repeated heating and cooling cycles, adding to the crucible's reliability and longevity.Paragraph 4:The advanced design of {Company Name}'s Silicon Graphite Crucible also minimizes contamination risks. The crucible surface possesses excellent chemical inertness and low reactivity with molten metals, preventing undesirable reactions or impurities. This feature is crucial for industries that adhere to strict quality standards and aim to produce high-purity end products. By significantly reducing contamination risks, the crucible ensures consistent product quality and minimizes the need for costly and time-consuming cleaning processes.Paragraph 5:The widespread adoption of Silicon Graphite Crucibles is expected to revolutionize several industries, including metal foundries, glass manufacturing, and electronics production. Thanks to the superior performance offered by {Company Name}'s crucibles, manufacturers can streamline their processes, achieve higher throughput, and reduce production bottlenecks. As a result, companies can improve their competitiveness, optimize resource utilization, and meet the growing demands of today's dynamic markets.Conclusion:{Company Name}'s groundbreaking Silicon Graphite Crucibles represent a significant milestone in the evolution of industrial manufacturing. With exceptional thermal conductivity, mechanical strength, and resistance to thermal shock, these crucibles overcome conventional limitations and bring forth new possibilities for various high-temperature processes. By increasing efficiency, minimizing contamination risks, and extending crucible lifespan, {Company Name} has revolutionized the industry, empowering manufacturers to thrive in an increasingly competitive environment.

Efficient Graphite Electrodes: Harnessing Power for Enhanced Performance

Graphite as Electrode Revolutionizes the Electrical IndustryWith the rapid advancement of technology in recent years, the need for high-performance electrical components has become increasingly essential. In this context, the development of a groundbreaking material called graphite as an electrode has captivated the attention of many industry experts. This innovative technology is set to revolutionize the electrical industry by providing a more efficient, sustainable, and cost-effective solution for various applications.Graphite has long been recognized for its unique properties and versatility in different industries. However, its potential as an electrode material remained largely untapped until recently. Traditionally, copper has been the preferred choice for electrical conductivity due to its excellent electrical and thermal conductivity. Nevertheless, the emergence of graphite electrodes offers numerous advantages that make it highly appealing for a wide range of applications.One of the most significant advantages of graphite electrodes is their exceptional heat resistance. Graphite has an incredibly high melting point, making it ideal for use in high-temperature environments. This property is particularly advantageous in applications such as electric arc furnaces, where extreme heat is generated during metal smelting or refining processes. By utilizing graphite electrodes, the industry can significantly increase energy efficiency and reduce operating costs.Additionally, the use of graphite electrodes promotes sustainability and environmental responsibility. Compared to traditional copper electrodes, graphite electrodes require significantly less energy during production. Furthermore, coppers' extraction and processing often have detrimental environmental impacts due to the runoff and waste generated during mining and refining processes. Graphite electrodes offer a more eco-friendly alternative, reducing the carbon footprint associated with electrical component manufacturing.The versatility of graphite electrodes further extends their potential applications in various industries. For instance, in the automotive industry, they are utilized in electric vehicles for fast charging, owing to their ability to withstand high currents and temperatures. Moreover, graphite electrodes find their utility in the manufacturing of solar panels, where their high conductivity enhances solar cell efficiency. Their lightweight properties also make them ideal for aerospace applications, where weight reduction is a crucial factor.The development and production of graphite electrodes have gained significant momentum with the involvement of industry leader XYZ Technologies (brand name removed). With years of expertise and innovative research, XYZ Technologies has made substantial advancements in the field, paving the way for the widespread adoption of this technology. The company has consistently invested in research and development to optimize the material properties of graphite electrodes, improving their efficiency and performance.XYZ Technologies' state-of-the-art production facilities ensure the highest quality graphite electrodes. Through a precise manufacturing process, they create electrodes with exceptional purity, conductivity, and dimensional accuracy. This commitment to quality and innovation has made XYZ Technologies a trusted provider of graphite electrodes to diverse industries globally. Their strong focus on customer satisfaction and continuous improvement has garnered them a reputable position in the market.The implications of graphite electrodes extend beyond individual industries, offering a significant contribution to the global energy transition. As countries strive to reduce carbon emissions, the demand for renewable energy sources such as solar and wind power continues to escalate. Graphite electrodes facilitate the efficient generation and transmission of renewable energy by enabling high-performance electrical systems, ultimately supporting a more sustainable future.In conclusion, the emergence of graphite electrodes as a groundbreaking material in the electrical industry presents a paradigm shift in electrical component manufacturing. With their exceptional heat resistance, sustainability, and versatility, graphite electrodes offer numerous advantages over traditional materials like copper. XYZ Technologies has played a pivotal role in developing this innovative technology, setting new standards in production quality, customer satisfaction, and overall market growth. As the world embraces renewable energy sources, graphite electrodes stand as a critical enabler in the global journey towards a greener and more sustainable future.

Revolutionary Induction Crucible Unveiled – A Game Changer in the Industry!

Title: Cutting-Edge Induction Crucible Enhances Industrial Manufacturing ProcessesSubtitle: Revolutionary Technology Boosts Efficiency, Safety, and Sustainability in Metal Casting IndustryDate: [Current Date][City], [State] - The metal casting industry is undergoing a groundbreaking transformation with the introduction of an innovative induction crucible [brand name removed]. This cutting-edge technology, developed by a leading industry player in collaboration with research experts, is set to revolutionize industrial manufacturing processes, offering unparalleled benefits in terms of efficiency, safety, and sustainability.With a focus on providing a comprehensive solution to the numerous challenges faced by metal casting industries worldwide, this induction crucible incorporates state-of-the-art features and advances in materials science. The crucible's composition allows for faster heating and melting of metals, significantly reducing production cycle times and energy consumption. By removing the brand name to be neutral in our reporting, we emphasize the broad industry impact rather than focusing on a particular company's product.Traditional crucibles have long been relied upon for melting and casting metals; however, they often present multiple limitations. The traditional crucibles used in foundries and other metalworking facilities are typically made of non-conductive materials, such as clay or graphite, which require external heating sources. In contrast, the induction crucible utilizes electromagnetic induction technology to generate heat directly within the metal, eliminating the need for external heat sources and enabling fast, efficient melting.The induction crucible's unique design ensures precise temperature control and uniform heating, eliminating hot spots and enabling consistent quality in castings. This advanced technology allows operators to monitor and adjust temperature settings in real-time, ensuring optimal conditions throughout the melting process. Such precise control not only enhances product quality but also saves time and costs associated with reworking or rejecting substandard castings.Safety is paramount in industrial manufacturing, and the induction crucible addresses this concern comprehensively. By eliminating the need for open flames or gas burners, the risk of accidents associated with traditional crucibles, such as fires, explosions, or employee injury, is significantly reduced. Additionally, the tightly sealed, closed-loop system of the induction crucible minimizes the risk of hazardous emissions, ensuring a safer working environment for employees and mitigating potential environmental impact.One of the critical advantages of the induction crucible [brand name removed] is its exceptional energy efficiency. The induction heating technology employed by this revolutionary crucible reduces energy consumption by up to 30% compared to traditional heat sources. This reduction in energy usage not only contributes to lower operating costs but also aligns with the global sustainability agenda by reducing greenhouse gas emissions and resource consumption."Our induction crucible represents the future of metal casting," says [Company Spokesperson]. "With its ability to improve efficiency, guarantee safety, and reduce environmental impact, this innovative technology will redefine industrial manufacturing processes globally."The induction crucible is specifically designed to cater to diverse industrial needs. Its versatility allows for efficient melting and casting of various metals, including steel, iron, aluminum, and copper. Additionally, the crucible's compact design and customizable features make it suitable for a wide range of factory sizes and layouts, ensuring easy integration and adaptability in existing manufacturing setups without disruptive renovations or expansions.The metal casting industry is eagerly anticipating the widespread implementation of this technological breakthrough. In addition to substantial improvements in efficiency and safety, the induction crucible also promises to have a positive socio-economic impact. By streamlining production processes, manufacturers can achieve higher productivity levels and meet increasing demand, consequently boosting job creation, local economies, and overall competitiveness.As this revolutionary induction crucible paves the way towards a new era in metal casting, manufacturers, industry experts, and environmentalists alike can look forward to a future where efficiency, safety, and sustainability are seamlessly integrated. With its ability to accelerate manufacturing processes, ensure operational safety, and minimize environmental impact, the induction crucible [brand name removed] holds great promise for reshaping the metal casting industry for the better.

Discover the Benefits of Custom Clay Graphite for Your Needs

Title: Innovative Graphene-Based Material Revolutionizes IndustriesIntroduction:Graphene, a remarkable one-atom thick layer of carbon, has been the focus of extensive research efforts due to its exceptional properties, which include high strength, electrical conductivity, and thermal stability. Building upon these properties, a leading materials company has successfully developed an advanced clay graphite composite material, poised to revolutionize industries worldwide. This groundbreaking development has the potential to reshape sectors ranging from electronics and energy storage to aerospace and manufacturing. Let us delve deeper into the extraordinary capabilities of this new material and its profound impact on various industries.Body:1. The Genesis of an Innovative Clay Graphite Composite:The revolutionary clay graphite custom (name removed) material is the result of years of ceaseless research and development efforts by a prominent materials company. By harnessing the extraordinary properties of graphene, the company's team of scientists has managed to create a composite material with outstanding characteristics. This new material marks a significant step forward in the pursuit of high-performance yet cost-effective solutions for modern industries.2. Advantages of Clay Graphite Composite:The clay graphite composite material offers numerous advantages over conventional materials, making it ideal for a wide range of applications. Firstly, its superior tensile strength ensures its viability in demanding environments, enhancing the durability and longevity of applications that require robust materials. Secondly, its remarkable electrical conductivity lends it well to industries that heavily rely on electrical systems and components. Thirdly, the material's thermal stability allows it to withstand extreme temperatures, making it invaluable in various high-heat applications.3. Potential Impact in Electronics Industry:In the ever-evolving field of electronics, the clay graphite composite material holds immense promise. With its exceptional electrical conductivity and thermal stability, this material can contribute to the development of more efficient and reliable electronic devices. From advanced semiconductors to flexible electronics, the material's characteristics open up new avenues for the creation of cutting-edge electronic components.4. Transformation in Energy Storage Solutions:Energy storage is a key challenge faced by modern society, be it in renewable energy systems or portable electronics. The introduction of clay graphite composite material in this sector has the potential to revolutionize energy storage solutions. Its high tensile strength and thermal stability make it an ideal candidate for advanced batteries and supercapacitors, offering enhanced energy density, longer battery life, and faster charging capabilities.5. Aerospace and Manufacturing Applications:The aerospace and manufacturing sectors are perpetually seeking materials that combine lightweight properties with superior strength and durability. The clay graphite composite material holds immense potential in fulfilling these requirements. Its remarkable strength-to-weight ratio makes it an excellent candidate for manufacturing components such as aircraft parts, automotive structures, and even space exploration equipment, where lightweight materials are crucial for overall performance and fuel efficiency.6. Environmental and Societal Impact:Moreover, the clay graphite composite material demonstrates promising environmental and societal impacts. Its exceptional electrical conductivity can improve energy efficiency, leading to reduced power consumption and carbon footprint in electronic devices and systems. Furthermore, the material's increased durability can lead to lower maintenance costs and extended product lifespan, contributing to fewer waste products and a more sustainable approach to manufacturing.Conclusion:In conclusion, the development of an advanced clay graphite composite material, leveraging the extraordinary properties of graphene, has brought about a new era of possibilities for various industries. From revolutionizing electronics and energy storage solutions to transforming aerospace and manufacturing applications, this material promises to enhance performance, sustainability, and efficiency across a vast array of sectors. With ongoing research and development efforts, the world can expect even greater breakthroughs in the integration of advanced materials, leading to a brighter and more innovative future.

Unlocking the Best Deals: The Latest Price Trends for Graphite Crucibles

Graphite Crucible Price Sees Significant Surge Amidst Growing DemandThe global graphite crucible market has been witnessing a significant surge in prices due to the increasing demand from various industries. A crucible is a ceramic or metal container used for melting and pouring materials at high temperatures, making it an essential tool in processes such as metal casting, glass manufacturing, and laboratory experiments. The rising prices can be attributed to several factors, including supply chain disruptions and the growing need for these crucibles in diverse applications.Graphite crucibles are predominantly used in the metallurgy industry for melting and refining metals, with steel and iron being the primary materials. These crucibles offer excellent thermal resistance, high thermal conductivity, and resistance to chemical corrosion, making them ideal for extreme temperature conditions. With the expansion of the global steel industry and the ever-increasing demand for automobiles, infrastructure development, and consumer goods, the need for graphite crucibles has soared.Additionally, the graphite crucibles find wide applications in the jewelry and gemstone industry for melting and casting precious metals like gold, silver, and platinum. The flourishing jewelry market, particularly in developing countries, has fueled the demand for these crucibles. Moreover, the increasing adoption of advanced technologies in the electronics sector has further amplified the requirement for graphite crucibles, as they play a crucial role in manufacturing processes such as smelting and alloying of metals.However, the soaring prices of graphite crucibles have become a matter of concern for industries dependent on them. Supply chain disruptions caused by the COVID-19 pandemic, coupled with the rising costs of raw materials and energy, have contributed to the upward surge in prices. The pandemic-induced lockdowns and restrictions have led to a shortage of graphite crucibles, affecting the production capacities of various industries. Furthermore, the closure of graphite mines, located predominantly in China, a major graphite producer, has led to limited availability of raw materials, exacerbating the supply-demand imbalance.To mitigate the impact of rising prices and ensure a consistent supply of graphite crucibles, companies in the industry are exploring alternative graphite sources and investing in research and development initiatives. Diversifying the supply chain and developing efficient recycling techniques for used crucibles are some strategies being adopted to enhance the availability and affordability of graphite crucibles.ABC Company is one such leading manufacturer and supplier of graphite crucibles, catering to diverse industries worldwide. Founded in the year 1990, ABC Company specializes in the production of high-quality graphite crucibles that adhere to international quality standards. With a strong focus on innovation and customer satisfaction, the company has gained a formidable reputation in the industry.ABC Company's state-of-the-art manufacturing facilities and efficient production processes enable them to deliver crucibles that meet the specific requirements of their clients. By leveraging advanced techniques and utilizing premium-grade materials, the company ensures the superior performance and durability of their crucibles.In response to the surging prices of graphite crucibles, ABC Company is committed to working closely with their customers and exploring cost-effective solutions. They are actively investing in research and development to enhance the efficiency of graphite crucibles, allowing industries to optimize their operations and minimize costs. Additionally, the company is striving to maintain transparency in their pricing structure and ensure fair and competitive prices for their customers.With the global demand for graphite crucibles projected to grow steadily in the coming years, the industry is poised for further evolution. As companies like ABC Company continue to innovate and adapt, the market can anticipate greater affordability and accessibility of graphite crucibles, paving the way for enhanced productivity and progress across various sectors.

Surging Sales of Graphite Electrodes: Impact on the Market Analyzed

Graphite Electrode Industry Sees Robust Growth in Sales The global graphite electrode industry has witnessed an impressive surge in sales over the past year, driven by increasing demand from various end-use sectors such as steel, aluminum, and silicon metals. The notable growth in sales can be attributed to several factors, including the rising consumption of steel in the construction and automotive sectors, as well as the rapid development of the electric vehicle market.Graphite electrodes are primarily used in electric arc furnaces (EAFs) for steel production, providing the necessary electrical conductivity to melt scrap metal and produce high-quality steel. As the construction and automotive industries continue to expand, the demand for steel is expected to surge, subsequently driving the growth of the graphite electrode market.Furthermore, the growing environmentally-conscious mindset of consumers has led to an increased adoption of electric vehicles (EVs) worldwide. Electric vehicles rely heavily on lightweight materials such as aluminum and silicon metals, both of which require graphite electrodes for their production. This has significantly boosted the demand for graphite electrodes in the aluminum and silicon metals industries, further contributing to the overall growth in sales.One of the key players in the graphite electrode industry, a renowned company with extensive experience, has experienced tremendous success in recent years, as reflected in their robust sales growth. This company, which specializes in the manufacturing and distribution of high-quality graphite electrodes, has witnessed a significant rise in sales thanks to its strong market presence and reputation for delivering superior products.A critical factor that sets this company apart from its competitors is its commitment to research and development. By continuously investing in innovation and advanced technologies, the company has been able to develop cutting-edge graphite electrode solutions that cater to the evolving needs and requirements of the steel, aluminum, and silicon metals industries. This has further solidified their position as a trusted supplier among their clientele.Moreover, the company's extensive distribution network has played a crucial role in its sales growth. With a wide-reaching distribution presence across key regions and markets, the company has been able to efficiently meet the increasing demand for graphite electrodes. This widespread availability of their products has not only bolstered their sales but has also solidified their reputation as a reliable and accessible supplier.Additionally, the company places great emphasis on customer satisfaction by providing exceptional after-sales services. They understand the importance of building long-term relationships with their customers, and thus, strive to offer comprehensive technical support and prompt assistance whenever needed. This dedication to customer service has proven to be a critical factor in their success, leading to increased customer loyalty and repeat business.Looking ahead, the global graphite electrode industry is expected to continue experiencing remarkable growth. The increased consumption of steel and the ongoing transition towards electric vehicles are projected to drive the demand for graphite electrodes even further. As the industry evolves, companies like the one mentioned above will play a vital role in providing innovative solutions and meeting the escalating demand.In conclusion, the graphite electrode industry is witnessing an impressive surge in sales, primarily driven by the robust demand from the steel, aluminum, and silicon metals sectors. The company discussed above, with its focus on research and development, extensive distribution network, and commitment to customer satisfaction, has emerged as a leading player in the industry. As the market continues to grow, it is anticipated that the sales of graphite electrodes will continue to rise, providing ample opportunities for further growth and expansion in the sector.

Top Graphite Crucible for Melting Aluminum: A Comprehensive Guide

Graphite Crucible for Melting Aluminum Revolutionizes Metal Casting IndustryAluminum, a widely used metal in various industries, requires precise and efficient methods for melting and casting. To address this need, a revolutionary new product has emerged on the market - the Graphite Crucible for Melting Aluminum. This innovative crucible promises to revolutionize the metal casting industry with its unparalleled performance and durability.Traditionally, metal casting had several limitations, including high energy consumption, long melting times, and limitations on the types of metals that could be melted. However, the Graphite Crucible for Melting Aluminum overcomes these challenges and sets a new standard for metal casting processes.Made from premium quality graphite material, the crucible boasts exceptional thermal conductivity, allowing for faster and more efficient melting of aluminum. This increased thermal conductivity translates into reduced energy consumption and shorter melting times. Manufacturers can now achieve higher production rates, resulting in cost savings and improved productivity.Additionally, the Graphite Crucible for Melting Aluminum showcases remarkable durability and resistance to thermal shock. This ensures the crucible can withstand the extreme temperatures required for aluminum melting without cracking or compromising its performance. The longevity and reliability of the crucible significantly reduce downtime and the need for frequent replacements, further optimizing the casting process.Moreover, this graphite crucible is compatible with various melting methods, including electric resistance furnaces, induction furnaces, and gas-fired furnaces. This versatility makes it a suitable choice for a wide range of industries, such as automotive, aerospace, construction, and many more.The manufacturing process of the Graphite Crucible for Melting Aluminum also adheres to strict quality standards. The crucible is meticulously designed and engineered to deliver consistent results, ensuring excellent casting outcomes. Its non-reactive nature prevents any contamination or interaction with the molten aluminum, resulting in high-quality castings.Companies in the metal casting industry can significantly benefit from implementing this innovative solution. By adopting the Graphite Crucible for Melting Aluminum, they can streamline their production processes, increase throughput, and enhance the overall quality of their cast aluminum products. Additionally, the reduced energy consumption and longevity of the crucible contribute to a more sustainable and environmentally friendly operation.One company that has successfully integrated this groundbreaking technology into their metal casting processes is {}. Established in {}, they have become a leader in the casting industry by consistently adopting and implementing the latest advancements. By utilizing the Graphite Crucible for Melting Aluminum, they have been able to enhance their production capacity, reduce costs, and improve the quality of their cast aluminum components.Company {}, with its commitment to innovation and continuous improvement, has embraced this new crucible technology. Through extensive testing and evaluation, they recognized the immense advantages this product offers in terms of efficiency, performance, and reliability. Their successful integration of the crucible into their operations sets an example for other companies to follow and highlights the transformative impact of this innovative product.In conclusion, the Graphite Crucible for Melting Aluminum is set to revolutionize the metal casting industry. Its exceptional thermal conductivity, durability, and versatility make it an invaluable tool for manufacturers across various sectors. Companies that adopt this cutting-edge technology will experience increased efficiency, reduced costs, and improved casting quality, propelling them to the forefront of the industry. With leading companies like {} embracing this innovation, the future of metal casting looks brighter than ever.

Discover the Ideal Crucible for Efficiently Melting Steel

Title: Cutting-Edge Crucible Revolutionizes Steel Melting ProcessesIntroduction:The steel industry is one of the most integral sectors that drive economic growth and development across the globe. Crucibles play a crucial role in the steel melting process, ensuring the efficient and effective transformation of raw materials into high-quality steel. Addressing the need for a reliable and advanced crucible for melting steel, a pioneering company, known for its commitment to innovation and technological advancements, has developed a groundbreaking solution that is set to revolutionize the industry.Best Crucible For Melting Steel:Leading the charge in creating a game-changing crucible, this innovative company has been at the forefront of research and development in materials science and metallurgy. Through years of extensive research and rigorous testing, they have successfully engineered a crucible that meets the demanding requirements of modern steel production.Utilizing cutting-edge technology, the crucible's design incorporates advanced heat-resistant materials, ensuring superior thermal stability and resistance to extreme temperatures. This groundbreaking feature allows for prolonged periods of operation without compromising the crucible's structural integrity.Furthermore, the company's crucible boasts exceptional resistance to chemical corrosion, making it a highly reliable choice for various steel alloys and other metal melting processes. This durability translates into improved productivity and reduced downtime for steel manufacturers, leading to enhanced operational efficiency and cost-effectiveness.Company Introduction:{Insert company name}, revered as an industry leader due to its relentless pursuit of excellence, has consistently pushed boundaries in the field of metallurgy. With a history spanning several decades, the company has garnered extensive expertise and experience, elevating it to the top echelons of the industry.Throughout its rich history, {Company Name} has earned a reputation for its unwavering commitment to providing innovative solutions that cater to the evolving needs of the steel industry. The company's research and development team comprises some of the finest minds in the field, equipped with state-of-the-art laboratories and cutting-edge technology to propel the boundaries of metallurgical advancements.The company's core values of quality, reliability, and sustainability are reflected in every aspect of their crucible manufacturing process. By adhering to stringent quality control measures, they ensure that their crucible meets the highest international standards, instilling confidence in steel manufacturers worldwide.Moreover, {Company Name} is dedicated to sustainability, striving to minimize its environmental impact throughout the production process. By embracing eco-friendly practices and supporting global initiatives, the company embodies responsible manufacturing principles.Conclusion:The introduction of the Best Crucible for Melting Steel by {Company Name} not only demonstrates their commitment to innovation but also showcases their prowess in developing cutting-edge solutions for the steel industry. The crucible's impressive features, such as enhanced thermal stability and resistance to chemical corrosion, will undoubtedly revolutionize steel melting processes, enhancing productivity and cost-effectiveness for manufacturers.As the steel industry continues to grow and adapt to new challenges, innovative advancements like the Best Crucible for Melting Steel will play a vital role in shaping its future. {Company Name}'s dedication to pushing the boundaries of metallurgical science ensures a brighter and more efficient future for steel production, ultimately benefiting industries and economies around the world.