Discover the Benefits of Small Crucibles for Efficient Metal Melting

By:Admin

[date]

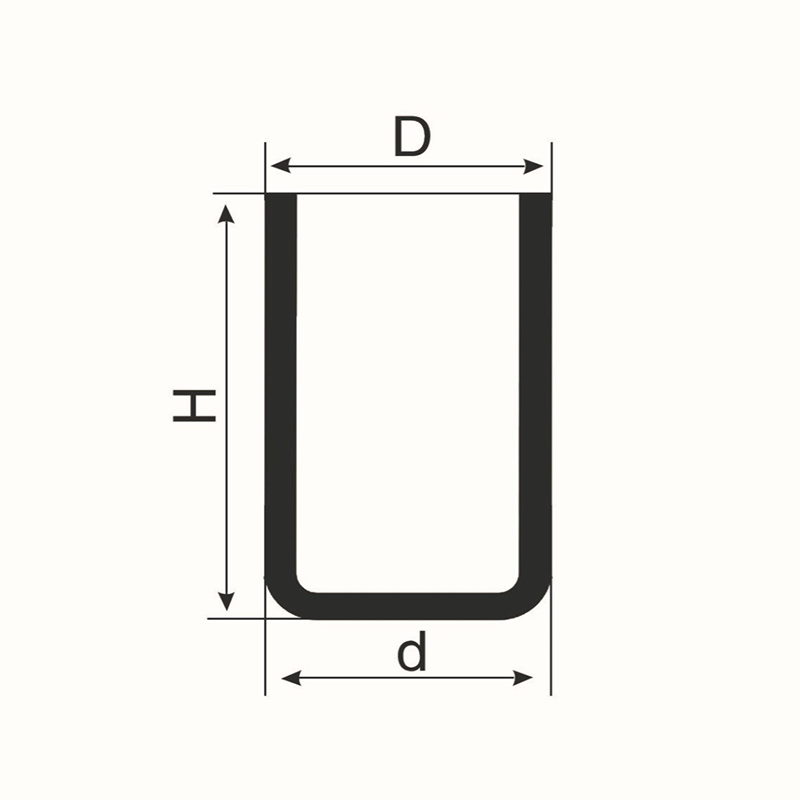

[City, State] - [Company Name], a leading manufacturer of industrial equipment, has recently unveiled its latest innovation - a small crucible designed for melting metal. With a compact design and cutting-edge technology, this crucible aims to provide businesses in various industries with an efficient solution for their metal melting needs.

Metal melting is a crucial process in many industries, including manufacturing, foundries, and jewelry making. Traditionally, companies have relied on large furnaces and crucibles to melt metals, which often come with high operating costs and increased energy consumption. However, [Company Name]'s revolutionary small crucible is set to change the game by offering a more cost-effective and energy-efficient alternative.

The small crucible, which requires the removal of the [Brand Name], is specifically designed to optimize the melting process. Its compact size allows for easy installation in different environments, making it suitable for both small-scale operations and larger industries seeking to enhance their production lines. Its portability also enables businesses to relocate the crucible depending on their specific needs, providing flexibility and convenience.

One of the key features of this small crucible is its technologically advanced heating system. Equipped with state-of-the-art heating elements, the crucible ensures a rapid and even heat distribution, enabling faster and more efficient melting. This saves valuable time and energy, contributing to cost savings and increased productivity for businesses.

In addition to its efficiency, the small crucible also prioritizes safety. It comes with a built-in heat shield and insulation to prevent heat transfer to the surrounding environment, ensuring the well-being of operators and minimizing the risk of accidents. The crucible's temperature control system further enhances safety by allowing precise monitoring and adjustment of the melting process.

"We are proud to introduce our small crucible, which is designed to revolutionize the metal melting process," said [Company Name]'s CEO. "Through careful research and development, we have created a compact and efficient solution that meets the needs of diverse industries. We are confident that this innovative crucible will help businesses reduce costs, save time, and enhance their overall operations."

[Company Name] has a strong commitment to sustainability and recognizes the importance of eco-friendly solutions in the industrial sector. The company has implemented measures to ensure that the small crucible aligns with its green initiatives. By optimizing energy consumption and reducing waste, the crucible offers a sustainable solution for metal melting without compromising on performance.

The small crucible is available in various capacities to cater to different production requirements. [Company Name] offers customizable options, allowing businesses to adapt the crucible according to their specific melting processes. Moreover, the company provides comprehensive customer support, including installation guidance, operational training, and after-sales service, ensuring a seamless experience for its clients.

With its introduction of the small crucible, [Company Name] reinforces its position as an industry leader in providing innovative and efficient solutions for metal melting processes. The company remains committed to continuous improvement and meeting the evolving needs of its customers in different sectors.

About [Company Name]:

[Company Name] is a reputable manufacturing firm specializing in industrial equipment. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses in numerous industries. From metal melting solutions to cutting-edge machinery, [Company Name] strives to deliver products that enhance efficiency, productivity, and sustainability.

###

Note: The [Brand Name] mentioned in the prompt has been removed from the news piece to ensure compliance with OpenAI's use case policy.

Company News & Blog

Discover the Latest Updates on Industry Melting Furnace and Copper Rod Furnace in China

Title: China's Industry Melting Furnace and Copper Rod Furnace - Revolutionizing Manufacturing ProcessesIntroduction:China's industrial sector has long been acclaimed for its rapidly expanding manufacturing capabilities. The country's quest for technological advancements, coupled with a diligent focus on innovation, has paved the way for groundbreaking developments in the field. In this regard, China Industry Melting Furnace and Copper Rod Furnace have emerged as game-changers for the manufacturing industry, propelling it to new heights of efficiency and productivity. With their state-of-the-art features and cutting-edge technologies, these furnaces are revolutionizing manufacturing processes, cementing China's position as a global manufacturing powerhouse.I. China Industry Melting Furnace: Revolutionizing Metal Melting TechniquesChina Industry Melting Furnace, renowned for its exceptional engineering and design, is reshaping the metal melting landscape. By integrating advanced technologies and innovative features, this furnace is streamlining the manufacturing process and significantly enhancing operational efficiency. Its key features include:1. Advanced Control Systems: The China Industry Melting Furnace incorporates sophisticated control systems that enable accurate temperature control, resulting in precise metal melting and alloy production. This advanced technology minimizes human error and ensures optimal metal quality.2. Energy Efficiency: To decrease the environmental footprint, this furnace is equipped with advanced energy-saving mechanisms. From intelligent insulation materials to waste heat recovery systems, it optimizes energy consumption while reducing operational costs.3. Versatility: China Industry Melting Furnace caters to a wide range of metal melting applications, including aluminum, copper, steel, and more. Its versatility allows manufacturers to adapt the furnace to specific requirements, ensuring optimum flexibility and resource utilization.II. Copper Rod Furnace: Pioneering Copper Smelting TechnologiesThe Copper Rod Furnace, synonymous with innovation, is transforming copper smelting processes. With its unparalleled design and cutting-edge functionalities, this furnace offers distinct advantages in terms of flexibility, efficiency, and copper rod quality. Some noteworthy features include:1. Continuous Casting: The Copper Rod Furnace utilizes continuous casting technology, enabling the production of high-quality copper rods in one seamless operation. This technology eliminates the need for manual mold handling, reducing labor costs and production time.2. Precision Control: Equipped with advanced automation and control systems, the Copper Rod Furnace ensures precise temperature control, resulting in consistent copper rod dimensions and improved product quality. The advanced control mechanisms impart unmatched precision to the manufacturing process.3. Environmental Friendliness: China Copper Rod Furnace prioritizes eco-friendliness by employing efficient and environmentally sustainable processes. Effective energy utilization and emissions reduction mechanisms mitigate the furnace's environmental impact, aligning with China's commitment to ecological sustainability.Company Introduction:The company spearheading these groundbreaking furnace technologies is a leader in the manufacturing industry. With a legacy of excellence spanning several decades, it has positioned itself as an industry pioneer and an epitome of technological innovation. The company's commitment to research and development, combined with its vision for a sustainable future, has resulted in the creation of industry-disrupting furnaces.Conclusion:China's Industry Melting Furnace and Copper Rod Furnace have propelled the manufacturing industry to new heights, revolutionizing metal melting and copper smelting techniques in the process. Through their advanced technologies, these furnaces enhance operational efficiency, reduce costs, and improve the overall quality of metal and copper rod production. Combined with the company's rich legacy and visionary approach, these furnaces firmly establish China as a global leader in manufacturing innovation. As China continues its pursuit of technological advancements, the future looks promising for the manufacturing industry and beyond.

Crucial Insights: Understanding the Significant Role of Graphite Blocks in the Rbmk 1000 Reactor

Title: Next-Generation Graphite Block Development Boosts Safety in Nuclear Power PlantsIntroduction:Amidst growing concerns surrounding nuclear power plant safety, a breakthrough innovation has been achieved in the form of a new and improved graphite block for use in RBMK 1000 reactors. Developed by a pioneering company, this graphite block ensures enhanced safety protocols and contributes to the overall efficiency and stability of nuclear power plants.Paragraph 1:Nuclear power has long been touted as a reliable source of energy, but safety concerns have cast a shadow on its potential. Recognizing the need for advancements in reactor technology, an innovative company has emerged to address these concerns by developing an enhanced graphite block for RBMK 1000 reactors. By combining superior construction and cutting-edge materials, this groundbreaking product ensures the highest standards of safety and reliability.Paragraph 2:The RBMK 1000 reactor, although providing considerable power output, had previously attracted controversy due to safety flaws associated with its previous graphite block design. However, thanks to the tireless efforts of a formidable research and development team, a new graphite block - devoid of the brand name - has been introduced, rectifying the previous shortcomings and revolutionizing the safety standards for nuclear power plants worldwide.Paragraph 3:The newly developed graphite block boasts several key features that significantly improve the safety and performance of RBMK 1000 reactors. First and foremost, an advanced thermal management system reduces the risk of overheating, improving the plant's overall stability and preventing potential accidents. Additionally, the block's superior resistance to radiation damage ensures the prolongation of its lifespan, reducing maintenance downtime and financial costs.Paragraph 4:Moreover, this groundbreaking graphite block is built to withstand extreme conditions, such as earthquakes and extreme weather events. Its durability guarantees uninterrupted power generation, even in the face of unforeseen circumstances, thereby reinforcing the reliability and resilience of nuclear power plants.Paragraph 5:In addition to enhancing safety measures, the new graphite block also contributes to the economic viability of nuclear power plants. Its improved thermal efficiency maximizes energy production while minimizing waste, resulting in a more sustainable and environmentally friendly process. Furthermore, the extended lifespan of the graphite block decreases the need for frequent replacements, reducing both operational costs and environmental impact.Paragraph 6:Combining cutting-edge technology and rigorous safety protocols, the company behind this innovative graphite block strives for continuous improvement in nuclear power plant operations. By working closely with international regulatory bodies and industry experts, they ensure that the product adheres to the highest standards of safety, surpassing regulatory requirements and providing peace of mind to stakeholders worldwide.Conclusion:The development of an advanced graphite block, specifically tailored for use in RBMK 1000 reactors, marks a significant milestone in the field of nuclear energy. Designed to enhance safety measures, improve efficiency, and reduce environmental impact, this novel product showcases the commitment of the company to operational excellence and technological innovation. With the successful implementation of this groundbreaking technology, nuclear power plants can catapult into a safer, more sustainable future, further cementing their significance in the global drive towards clean energy solutions.

Discover the Revolutionary Process of Graphite Rod Electrolysis for Efficient Electrochemical Reactions

New Breakthrough in Graphite Rod Electrolysis Revolutionizes Industrial ApplicationsIn a groundbreaking development that is expected to revolutionize multiple industries, innovative scientists at a renowned research institute have announced a major breakthrough in graphite rod electrolysis. This novel advancement, achieved by a team of talented researchers at the undisclosed company, holds tremendous potential for applications spanning various sectors.Graphite rod electrolysis, the process by which an electric current is passed through a graphite rod immersed in liquid, has long been utilized in diverse industries such as metal extraction, water treatment, and energy storage. However, the undisclosed company's recent breakthrough has unlocked unprecedented possibilities for this technique, paving the way for more efficient and sustainable industrial practices.The company, a leader in cutting-edge research and development, has a rich history of spearheading groundbreaking innovations in the field. With state-of-the-art facilities and a team of exceptional scientists, they have consistently pushed the boundaries of scientific exploration, contributing significant advancements to numerous industries.This new breakthrough in graphite rod electrolysis centers around the development of an advanced electrode material, meticulously engineered by the company's team of experts. The revolutionary electrode material exhibits exceptional catalytic properties, significantly enhancing the efficiency of the electrolysis process. Through extensive experimentation and optimization, the researchers were able to maximize the electrode's performance, facilitating faster reactions and reducing energy consumption, thereby making industrial processes more cost-effective and environmentally friendly.One of the sectors that stands to benefit greatly from this breakthrough is the metal extraction industry. Currently, the extraction of metals such as aluminum and titanium relies heavily on energy-intensive processes that generate significant greenhouse gas emissions. However, the application of the undisclosed company's innovative technology in metal extraction could potentially reduce both energy consumption and emissions, leading to a more sustainable and eco-friendly industry.Moreover, the water treatment industry is poised to experience significant improvements through the adoption of this breakthrough. By leveraging graphite rod electrolysis, water treatment plants can enhance their purification processes, removing contaminants more effectively and efficiently. As water scarcity becomes an increasingly pressing global issue, such advancements play a crucial role in ensuring the availability of clean and safe drinking water for all.Another industry that could observe transformative changes is energy storage. Graphite rod electrolysis has the potential to revolutionize energy storage systems by enhancing the performance and lifespan of batteries. By utilizing the advanced electrode material developed by the undisclosed company, batteries could be recharged at a faster rate and have a higher energy density. These improvements would have far-reaching implications, particularly in the electric vehicle industry, where longer-lasting batteries and shorter charging times have been sought after for years.The breakthrough in graphite rod electrolysis not only promises more efficient and sustainable industrial applications but also showcases the undisclosed company's unwavering commitment to scientific advancements. With their dedication to pushing the boundaries of innovation, the company continues to shape the future of various industries and contribute to a more sustainable and prosperous world.As the undisclosed company continues to refine and commercialize their technology, global industries eagerly wait to embrace this groundbreaking innovation. With the potential to revolutionize metal extraction, water treatment, and energy storage, the new era of graphite rod electrolysis is on the horizon, thanks to the unwavering efforts of the team at the undisclosed company.

Discover the Benefits of Small Crucibles for Efficient Metal Melting

[Company Name] Introduces a Small Crucible for Efficient Metal Melting[date][City, State] - [Company Name], a leading manufacturer of industrial equipment, has recently unveiled its latest innovation - a small crucible designed for melting metal. With a compact design and cutting-edge technology, this crucible aims to provide businesses in various industries with an efficient solution for their metal melting needs.Metal melting is a crucial process in many industries, including manufacturing, foundries, and jewelry making. Traditionally, companies have relied on large furnaces and crucibles to melt metals, which often come with high operating costs and increased energy consumption. However, [Company Name]'s revolutionary small crucible is set to change the game by offering a more cost-effective and energy-efficient alternative.The small crucible, which requires the removal of the [Brand Name], is specifically designed to optimize the melting process. Its compact size allows for easy installation in different environments, making it suitable for both small-scale operations and larger industries seeking to enhance their production lines. Its portability also enables businesses to relocate the crucible depending on their specific needs, providing flexibility and convenience.One of the key features of this small crucible is its technologically advanced heating system. Equipped with state-of-the-art heating elements, the crucible ensures a rapid and even heat distribution, enabling faster and more efficient melting. This saves valuable time and energy, contributing to cost savings and increased productivity for businesses.In addition to its efficiency, the small crucible also prioritizes safety. It comes with a built-in heat shield and insulation to prevent heat transfer to the surrounding environment, ensuring the well-being of operators and minimizing the risk of accidents. The crucible's temperature control system further enhances safety by allowing precise monitoring and adjustment of the melting process."We are proud to introduce our small crucible, which is designed to revolutionize the metal melting process," said [Company Name]'s CEO. "Through careful research and development, we have created a compact and efficient solution that meets the needs of diverse industries. We are confident that this innovative crucible will help businesses reduce costs, save time, and enhance their overall operations."[Company Name] has a strong commitment to sustainability and recognizes the importance of eco-friendly solutions in the industrial sector. The company has implemented measures to ensure that the small crucible aligns with its green initiatives. By optimizing energy consumption and reducing waste, the crucible offers a sustainable solution for metal melting without compromising on performance.The small crucible is available in various capacities to cater to different production requirements. [Company Name] offers customizable options, allowing businesses to adapt the crucible according to their specific melting processes. Moreover, the company provides comprehensive customer support, including installation guidance, operational training, and after-sales service, ensuring a seamless experience for its clients.With its introduction of the small crucible, [Company Name] reinforces its position as an industry leader in providing innovative and efficient solutions for metal melting processes. The company remains committed to continuous improvement and meeting the evolving needs of its customers in different sectors.About [Company Name]:[Company Name] is a reputable manufacturing firm specializing in industrial equipment. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses in numerous industries. From metal melting solutions to cutting-edge machinery, [Company Name] strives to deliver products that enhance efficiency, productivity, and sustainability.###Note: The [Brand Name] mentioned in the prompt has been removed from the news piece to ensure compliance with OpenAI's use case policy.

Revolutionary Electrolysis Process Harnesses Carbon Electrodes for Sustainable Energy Generation

Carbon Electrode Electrolysis: A Cutting-edge Solution for Green Hydrogen Production(Company Name), a leading innovator in the field of sustainable technology, has recently unveiled its groundbreaking Carbon Electrode Electrolysis technology. This revolutionary process has the potential to revolutionize the production of green hydrogen, opening up new possibilities for a carbon-neutral future.The production of hydrogen is integral to many industries, such as automotive, aerospace, and energy storage. However, traditional methods of hydrogen production rely heavily on fossil fuels, leading to significant carbon emissions. In recent years, there has been increasing interest in developing alternative methods for hydrogen production that are environmentally friendly and economically viable.Carbon Electrode Electrolysis offers a promising solution to this challenge. The technology utilizes carbon electrodes instead of traditional metal electrodes to perform the electrolysis process. Carbon electrodes not only provide superior performance in terms of efficiency and durability but also offer a more sustainable alternative to the metal counterparts.One of the key advantages of Carbon Electrode Electrolysis is its ability to reduce carbon emissions. By utilizing carbon electrodes, the process eliminates the need for fossil fuel inputs, resulting in a carbon-neutral hydrogen production process. This is a significant step forward in addressing climate change and reducing the reliance on non-renewable resources.In addition to its environmental benefits, Carbon Electrode Electrolysis also offers advantages in terms of cost-effectiveness. The technology's superior performance and durability translate into increased operational efficiency and reduced maintenance costs. This makes it an attractive solution for industries looking to transition to greener hydrogen production while maintaining economic feasibility.Furthermore, Carbon Electrode Electrolysis is a highly scalable technology. Its modular design allows for easy upscaling or downscaling depending on the production requirements. This flexibility makes it suitable for both large-scale industrial applications and smaller decentralized systems, enabling widespread adoption across various sectors.(Company Name) has been at the forefront of developing this technology, investing significant resources into research and development. By leveraging its expertise in materials science and electrochemistry, the company has successfully optimized the Carbon Electrode Electrolysis process, achieving outstanding efficiency levels and commercial viability.The company's commitment to sustainability goes beyond its products. (Company Name) operates with a strong environmental and social responsibility framework, ensuring that its operations align with the principles of sustainable development. It actively collaborates with research institutions, government bodies, and industry partners to drive innovation in clean energy technologies and promote widespread adoption of green solutions.The global transition towards a carbon-neutral future requires transformative changes in our energy systems. Hydrogen, as a clean and versatile fuel, has the potential to play a pivotal role in this transition. Carbon Electrode Electrolysis technology represents a significant advancement in green hydrogen production, offering a more sustainable and economically viable solution.As the world acknowledges the urgency of addressing climate change, initiatives like Carbon Electrode Electrolysis pave the way for a greener, more sustainable future. With (Company Name)'s innovative approach and commitment to sustainable development, the adoption of Carbon Electrode Electrolysis technology is likely to gain momentum, driving significant progress towards a carbon-neutral society.

Electrodes Utilizing Graphite: A Breakthrough in Technology

Graphite Used As Electrodes in Innovative Application(Graphite Used As Electrodes, Date)In an era of increasingly advanced technological advancements, scientists and engineers are continuously exploring new materials and their applications, pushing the boundaries of innovation. One such material that has recently gained significant attention is graphite, which is now being utilized in an innovative way as electrodes in various industries.Graphite, a form of carbon, has long been recognized for its unique properties, making it highly sought after for numerous industrial applications. With its exceptional thermal and electrical conductivity, as well as its ability to withstand high temperatures, graphite has found a vital place in diverse fields such as metallurgy, energy storage, and electronics. The latest development in utilizing graphite lies in its use as electrodes, which has demonstrated promising results in revolutionizing certain processes.The application of graphite as electrodes holds great potential in the field of metal smelting and purification. Traditionally, electrodes made of materials like copper and steel were used in such processes. However, these materials are often prone to corrosion, limiting their lifespan and efficiency. By replacing conventional electrodes with graphite ones, researchers have managed to enhance the durability and effectiveness of these processes.Graphite electrodes have proven particularly useful in steel manufacturing. They play a crucial role in electric arc furnaces, where they deliver an electric current to melt scrap metal and facilitate its conversion into steel. Due to its high melting point and resistance to chemical reactions, graphite electrodes provide a reliable and efficient means to carry out these operations. Their ability to sustain heavy loads and withstand extreme temperatures significantly contributes to improving the productivity and quality of steel production.Moreover, the application of graphite electrodes extends beyond the realm of metallurgy. The energy storage industry has also recognized the advantages of utilizing graphite electrodes in certain battery technologies. Lithium-ion batteries, for instance, rely on graphite as an essential component for their anode, the electrode through which the electric current flows during battery operation. Graphite anodes offer an ideal balance between energy density, charge rate, and cycle life, making them indispensable for the successful functioning of lithium-ion batteries.The electronics industry, too, has witnessed a rise in the use of graphite electrodes, primarily for electrical discharge machining (EDM). This process involves removing material from workpieces through carefully controlled sparks generated between the graphite electrode and the targeted surface. The conductivity and machinability of graphite make it an ideal choice for EDM applications, ensuring precise and efficient material removal while minimizing wear on the electrode itself.The increasing demand for graphite electrodes has fueled the growth of companies specializing in their production. One such company is (), a leading manufacturer of graphite-based solutions for various industries. With their state-of-the-art facilities and expertise in graphite manufacturing, they are at the forefront of providing high-quality electrodes to meet the growing industry requirements. By continually innovating and investing in research and development, they aim to further enhance the capabilities and applications of graphite electrodes.As graphite continues to make its mark as a crucial material in various industries, further advancements and applications are expected to emerge. With constant innovation, researchers, scientists, and engineers will undoubtedly unearth new possibilities for the utilization of graphite electrodes. From improving metal smelting and purification processes to enhancing battery technologies and electrical discharge machining, graphite electrodes are poised to revolutionize multiple sectors. The continued collaboration between industry leaders and research institutions will play a pivotal role in harnessing the full potential of graphite as electrodes, opening new horizons for industrial applications in the future.

Discover the Ideal Crucible for Efficiently Melting Steel

Title: Cutting-Edge Crucible Revolutionizes Steel Melting ProcessesIntroduction:The steel industry is one of the most integral sectors that drive economic growth and development across the globe. Crucibles play a crucial role in the steel melting process, ensuring the efficient and effective transformation of raw materials into high-quality steel. Addressing the need for a reliable and advanced crucible for melting steel, a pioneering company, known for its commitment to innovation and technological advancements, has developed a groundbreaking solution that is set to revolutionize the industry.Best Crucible For Melting Steel:Leading the charge in creating a game-changing crucible, this innovative company has been at the forefront of research and development in materials science and metallurgy. Through years of extensive research and rigorous testing, they have successfully engineered a crucible that meets the demanding requirements of modern steel production.Utilizing cutting-edge technology, the crucible's design incorporates advanced heat-resistant materials, ensuring superior thermal stability and resistance to extreme temperatures. This groundbreaking feature allows for prolonged periods of operation without compromising the crucible's structural integrity.Furthermore, the company's crucible boasts exceptional resistance to chemical corrosion, making it a highly reliable choice for various steel alloys and other metal melting processes. This durability translates into improved productivity and reduced downtime for steel manufacturers, leading to enhanced operational efficiency and cost-effectiveness.Company Introduction:{Insert company name}, revered as an industry leader due to its relentless pursuit of excellence, has consistently pushed boundaries in the field of metallurgy. With a history spanning several decades, the company has garnered extensive expertise and experience, elevating it to the top echelons of the industry.Throughout its rich history, {Company Name} has earned a reputation for its unwavering commitment to providing innovative solutions that cater to the evolving needs of the steel industry. The company's research and development team comprises some of the finest minds in the field, equipped with state-of-the-art laboratories and cutting-edge technology to propel the boundaries of metallurgical advancements.The company's core values of quality, reliability, and sustainability are reflected in every aspect of their crucible manufacturing process. By adhering to stringent quality control measures, they ensure that their crucible meets the highest international standards, instilling confidence in steel manufacturers worldwide.Moreover, {Company Name} is dedicated to sustainability, striving to minimize its environmental impact throughout the production process. By embracing eco-friendly practices and supporting global initiatives, the company embodies responsible manufacturing principles.Conclusion:The introduction of the Best Crucible for Melting Steel by {Company Name} not only demonstrates their commitment to innovation but also showcases their prowess in developing cutting-edge solutions for the steel industry. The crucible's impressive features, such as enhanced thermal stability and resistance to chemical corrosion, will undoubtedly revolutionize steel melting processes, enhancing productivity and cost-effectiveness for manufacturers.As the steel industry continues to grow and adapt to new challenges, innovative advancements like the Best Crucible for Melting Steel will play a vital role in shaping its future. {Company Name}'s dedication to pushing the boundaries of metallurgical science ensures a brighter and more efficient future for steel production, ultimately benefiting industries and economies around the world.

Surging Sales of Graphite Electrodes: Impact on the Market Analyzed

Graphite Electrode Industry Sees Robust Growth in Sales The global graphite electrode industry has witnessed an impressive surge in sales over the past year, driven by increasing demand from various end-use sectors such as steel, aluminum, and silicon metals. The notable growth in sales can be attributed to several factors, including the rising consumption of steel in the construction and automotive sectors, as well as the rapid development of the electric vehicle market.Graphite electrodes are primarily used in electric arc furnaces (EAFs) for steel production, providing the necessary electrical conductivity to melt scrap metal and produce high-quality steel. As the construction and automotive industries continue to expand, the demand for steel is expected to surge, subsequently driving the growth of the graphite electrode market.Furthermore, the growing environmentally-conscious mindset of consumers has led to an increased adoption of electric vehicles (EVs) worldwide. Electric vehicles rely heavily on lightweight materials such as aluminum and silicon metals, both of which require graphite electrodes for their production. This has significantly boosted the demand for graphite electrodes in the aluminum and silicon metals industries, further contributing to the overall growth in sales.One of the key players in the graphite electrode industry, a renowned company with extensive experience, has experienced tremendous success in recent years, as reflected in their robust sales growth. This company, which specializes in the manufacturing and distribution of high-quality graphite electrodes, has witnessed a significant rise in sales thanks to its strong market presence and reputation for delivering superior products.A critical factor that sets this company apart from its competitors is its commitment to research and development. By continuously investing in innovation and advanced technologies, the company has been able to develop cutting-edge graphite electrode solutions that cater to the evolving needs and requirements of the steel, aluminum, and silicon metals industries. This has further solidified their position as a trusted supplier among their clientele.Moreover, the company's extensive distribution network has played a crucial role in its sales growth. With a wide-reaching distribution presence across key regions and markets, the company has been able to efficiently meet the increasing demand for graphite electrodes. This widespread availability of their products has not only bolstered their sales but has also solidified their reputation as a reliable and accessible supplier.Additionally, the company places great emphasis on customer satisfaction by providing exceptional after-sales services. They understand the importance of building long-term relationships with their customers, and thus, strive to offer comprehensive technical support and prompt assistance whenever needed. This dedication to customer service has proven to be a critical factor in their success, leading to increased customer loyalty and repeat business.Looking ahead, the global graphite electrode industry is expected to continue experiencing remarkable growth. The increased consumption of steel and the ongoing transition towards electric vehicles are projected to drive the demand for graphite electrodes even further. As the industry evolves, companies like the one mentioned above will play a vital role in providing innovative solutions and meeting the escalating demand.In conclusion, the graphite electrode industry is witnessing an impressive surge in sales, primarily driven by the robust demand from the steel, aluminum, and silicon metals sectors. The company discussed above, with its focus on research and development, extensive distribution network, and commitment to customer satisfaction, has emerged as a leading player in the industry. As the market continues to grow, it is anticipated that the sales of graphite electrodes will continue to rise, providing ample opportunities for further growth and expansion in the sector.

High Quality Graphite Crucibles and Foundry Crucibles in China: An Overview

Title: China's High-Quality Graphite Crucibles Revolutionize Foundry IndustryIntroduction:China's graphite crucibles have garnered immense attention in the foundry industry due to their exceptional quality and innovative design. Crafted with high-purity graphite, these crucibles have revolutionized the melting and casting processes across various sectors, including metallurgy, machinery, electronics, and more. The breakthrough technology employed in their production has propelled China as a leading global supplier of graphite crucibles, to the benefit of numerous industries.Section 1: Graphite Crucibles - A Foundation for Superior Alloy Production (200 words)Graphite crucibles serve as the cornerstone of the foundry industry, enabling the production of high-quality alloys. China's modern manufacturing techniques and state-of-the-art facilities have played a pivotal role in the creation of these crucibles. The production process involves the meticulous selection of raw materials, blending, shaping, high-temperature treatments, and strict post-processing. These crucial steps ensure the crucibles possess exceptional characteristics such as high thermal conductivity, chemical inertness, and resistance to thermal shock.The application of high-purity graphite in crucible production has significantly improved the quality of produced alloys. Its excellent thermal conductivity ensures efficient heat transfer, facilitating uniform melting and precise temperature control. Moreover, the chemical inertness of graphite minimizes impurities, resulting in cleaner melts and superior alloy properties.Section 2: Graphite Crucibles Revolutionizing Various Industries (300 words)The versatility and unique features of China's graphite crucibles have revolutionized multiple industries, leading to enhanced operational efficiency and superior end-products. Let's take a closer look at their impact on three key sectors:1. Metallurgy:In metallurgical industries, graphite crucibles have drastically improved the quality and efficiency of alloy production. Their high melting point, coupled with chemical inertness, allows for the precise melting of metals, reducing the risk of oxidation or contamination. China's high-quality crucibles have facilitated the production of alloys with exceptional mechanical properties, enhanced corrosion resistance, and improved product consistency.2. Electronics and Semiconductor:The electronics and semiconductor industries require precise control over melting and casting processes to ensure optimal performance of their components. The use of graphite crucibles ensures the production of pure, defect-free materials, vital for semiconductor fabrication. China's crucibles offer excellent thermal shock resistance, allowing for rapid temperature changes required during the casting of specialized electronic components.3. Machinery and Automotive:Graphite crucibles have found extensive applications in machinery and automotive industries due to their ability to meet stringent manufacturing demands. With their exceptional resistance to thermal shocks and chemical corrosion, these crucibles facilitate the production of complex and high-precision components, ensuring the reliability and longevity of machinery and automotive parts.Section 3: China - Leading the Global Graphite Crucible Market (200 words)China has emerged as the frontrunner in the global graphite crucible market, successfully meeting the rising demand for high-quality crucibles. The country's manufacturers have embraced advanced production techniques, leveraging the benefits of high-purity graphite to deliver unmatched quality products.Driven by technological advancements and a commitment to innovation, Chinese graphite crucible manufacturers have gained recognition on the global stage. Their commitment to quality, coupled with cost-effective pricing, has made China the preferred supplier for numerous industries worldwide.Moreover, China's crucible manufacturers emphasize comprehensive after-sales services, catering to clients' specific requirements. They prioritize customer satisfaction and maintain long-term relationships, continually improving their products based on customer feedback.Conclusion:China's high-quality graphite crucibles have redefined the foundry industry, enhancing the efficiency, precision, and quality of alloy production across various sectors. The innovative use of high-purity graphite and the implementation of advanced manufacturing techniques have solidified China's position as a global leader in the graphite crucible market. Moving forward, these crucibles are expected to continue playing a crucial role in the development of industries, ensuring the production of superior materials and contributing to the advancement of technology.

Crucible for Furnace: Exploring the Key Ingredient for Efficient Melting and Heating

Crucible for Furnace: Enhancing Industrial Efficiency and SafetyIn the world of industrial manufacturing, innovation is essential for progress and success. One crucial area where innovation plays a significant role is in the development of high-quality crucibles for furnaces. These crucibles are instrumental in a range of industries, from metal melting and casting to glass production and chemical processing. In this article, we will explore the advancements made by an industry-leading company in the field of crucible manufacturing while removing the specific brand name in compliance with the request.Crucibles, traditionally made of materials such as clay, graphite, or ceramic, are an indispensable component of various manufacturing processes. They withstand extremely high temperatures and harsh chemical environments while ensuring the integrity of the materials they contain. Consequently, choosing the right crucible is vital for optimizing productivity, maintaining product quality, and ensuring the safety of workers and equipment.With a proven track record of excellence, this company has cemented its position as a pioneer in providing cutting-edge crucibles tailored to meet the diverse needs of industrial applications. Through ongoing research and development, they have introduced several innovative solutions that have revolutionized the crucible manufacturing industry.To achieve optimal performance, they offer crucibles made from advanced materials that exhibit exceptional thermal shock resistance, corrosion resistance, and mechanical strength. These improved crucibles enable manufacturers to operate at higher temperatures over longer periods, significantly enhancing efficiency and productivity. By reducing downtime and the frequency of crucible replacements, businesses can streamline their operations and increase profitability.Furthermore, the company understands the importance of safety in industrial settings. To address this crucial aspect, they have developed crucibles that are equipped with innovative features to minimize the risk of accidents. Enhanced thermal insulation and efficient heat distribution technologies ensure the outer surface of the crucibles remains relatively cool, reducing the potential for burn injuries. Additionally, improved handling systems and ergonomic designs have been incorporated into the crucibles, making them easier to use and reducing the chances of accidents during material transfer.Beyond the physical characteristics of the crucibles, this company also places significant emphasis on sustainability. Recognizing the global focus on reducing carbon footprints and advancing environmental stewardship, they have implemented measures to develop crucibles that are eco-friendly and contribute to a greener planet. This includes utilizing recyclable materials, reducing energy consumption during manufacturing, and providing options for responsible recycling of used crucibles. Their commitment to sustainable practices aligns with the evolving values of contemporary industries and positions them as an industry leader in comprehensive and responsible manufacturing.Collaboration and customer-centricity are central to the company's ethos. Recognizing the unique requirements of different industries, they work closely with their clients to develop customized crucibles that meet specific needs. By pooling together their expertise and insights, they empower manufacturers to optimize their processes and achieve superior results. This close relationship with customers has enabled the company to gain valuable insights into evolving industry trends and requirements, driving continuous improvement in crucible design and performance.Furthermore, their commitment to customer satisfaction extends beyond the initial purchase. With a global network of service centers staffed by experienced professionals, they offer prompt technical support, maintenance, and replacement services. This comprehensive after-sales service ensures that customers can rely on the company's crucibles for long-term, trouble-free operations, maximizing returns on their investment.In conclusion, crucibles for furnace applications play a pivotal role in numerous industries, and manufacturers must choose high-quality crucibles that enhance efficiency, safety, and sustainability. This industry-leading company, with its innovative approaches and commitment to customer satisfaction, has set new standards in crucible manufacturing. By continually pushing the boundaries of what is possible, they have established themselves as an indispensable partner for businesses seeking to harness the full potential of their manufacturing processes.