Product Video

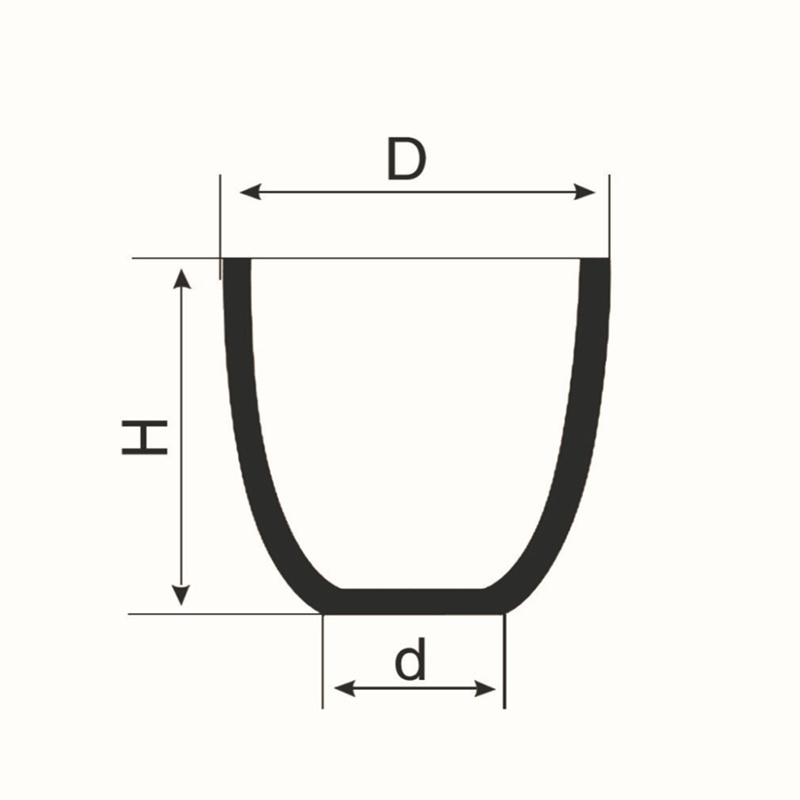

Our crucibles are manufactured using the world's most advanced cold isostatic molding method, ensuring isotropic properties, high density, strength, uniformity, and defect-free production. We offer a wide range of products, including resin bond and clay bond crucibles, providing the best solution for different customers to extend their service life. Our crucibles also have a longer lifespan than ordinary crucibles, lasting 2-5 times longer. They are resistant to chemical attacks, thanks to advanced materials and glaze recipes. The use of graphite materials and isostatic pressing enables our crucibles to have a thin wall and high thermal conductivity, ensuring fast heat conduction. Our crucibles can withstand high temperatures ranging from 400-1600℃, providing reliable performance for various applications. We use only the main raw materials of well-known foreign brands and imported raw materials for our glazes, ensuring stable and reliable quality.When asking for a quotation, please provide the following details:

Using and Storing Crucibles Precautions

1.Place the crucible in a dry area or within a wooden frame to prevent moisture accumulation. 2.Use crucible tongs that match the shape of the crucible to avoid causing damage to it. 3.Feed the crucible with an amount of material that is within its capacity; avoid overloading it to prevent bursting. 4.Tap the crucible while removing slag to prevent damage to its body. 5.Place kelp, carbon powder, or asbestos powder on the pedestal and ensure that it matches the bottom of the crucible. Put the crucible at furnace’s center. 6.Keep a safe distance from the furnace, and secure crucible firmly with a wedge. 7.Avoid using an excess amount of oxidizer to extend the life of the crucible.Technical Specification

| Item | Code | Height | Outer Diameter | Bottom Diameter |

| CU210 | 570# | 500 | 605 | 320 |

| CU250 | 760# | 630 | 610 | 320 |

| CU300 | 802# | 800 | 610 | 320 |

| CU350 | 803# | 900 | 610 | 320 |

| CU500 | 1600# | 750 | 770 | 330 |

| CU600 | 1800# | 900 | 900 | 330 |

FAQ

Do you offer OEM manufacturing?

--Yes! We can manufacture products to your requested specifications.

Can you arrange delivery through our shipping agent?

--Absolutely, we can arrange delivery through your preferred shipping agent.

What is your delivery time?

--Delivery in stock products typically takes 5-10 days . It may take 15-30 days for customized products.

How about your working hours?

--Our customer service team is available in 24h. We will be happy to reply you at anytime.