About This Item

Our Silicon carbide crucibles are used in a variety of industrial applications, like metallurgy, semiconductor manufacturing,glass production, and the chemical industry. Our Silicon carbide crucibles have the advantage of high-temperature melting and resistance to chemical attack. They are known for their excellent thermal conductivity,high thermal shock resistance, and resistance to chemical attack.Technical Specification

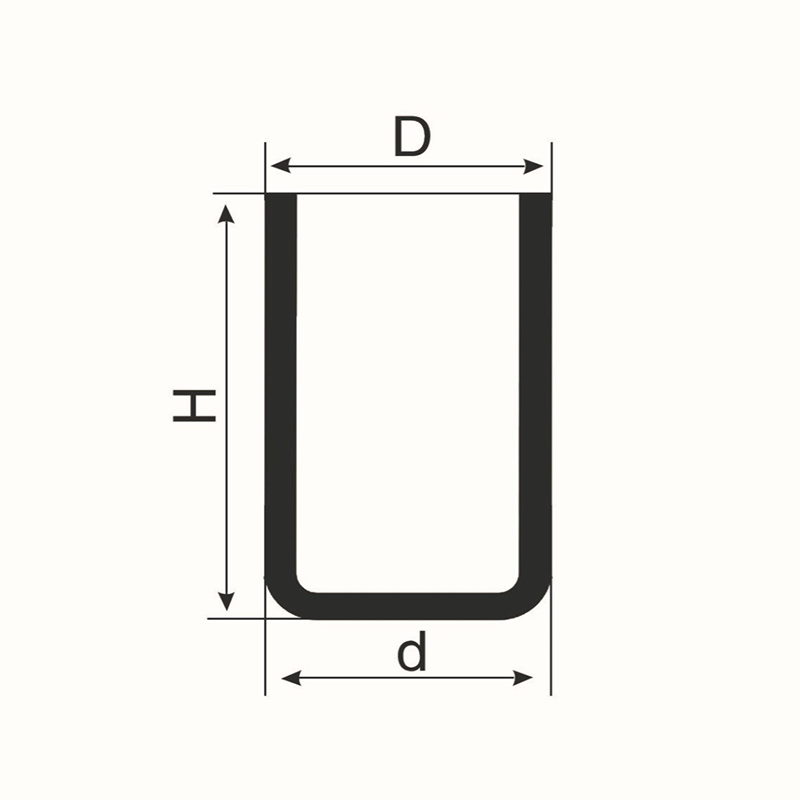

| Item | Model | Outer Diameter diameter) | Height | Inside Diameter | Bottom Diameter | ||||

| 1 | 80 | 330 | 410 | 265 | 230 | ||||

| 2 | 100 | 350 | 440 | 282 | 240 | ||||

| 3 | 110 | 330 | 380 | 260 | 205 | ||||

| 4 | 200 | 420 | 500 | 350 | 230 | ||||

| 5 | 201 | 430 | 500 | 350 | 230 | ||||

| 6 | 350 | 430 | 570 | 365 | 230 | ||||

| 7 | 351 | 430 | 670 | 360 | 230 | ||||

| 8 | 300 | 450 | 500 | 360 | 230 | ||||

| 9 | 330 | 450 | 450 | 380 | 230 | ||||

| 10 | 350 | 470 | 650 | 390 | 320 | ||||

| 11 | 360 | 530 | 530 | 460 | 300 | ||||

| 12 | 370 | 530 | 570 | 460 | 300 | ||||

| 13 | 400 | 530 | 750 | 446 | 330 | ||||

| 14 | 450 | 520 | 600 | 440 | 260 | ||||

| 15 | 453 | 520 | 660 | 450 | 310 | ||||

| 16 | 460 | 565 | 600 | 500 | 310 | ||||

| 17 | 463 | 570 | 620 | 500 | 310 | ||||

| 18 | 500 | 520 | 650 | 450 | 360 | ||||

| 19 | 501 | 520 | 700 | 460 | 310 | ||||

| 20 | 505 | 520 | 780 | 460 | 310 | ||||

| 21 | 511 | 550 | 660 | 460 | 320 | ||||

| 22 | 650 | 550 | 800 | 480 | 330 | ||||

| 23 | 700 | 600 | 500 | 550 | 295 | ||||

| 24 | 760 | 615 | 620 | 550 | 295 | ||||

| 25 | 765 | 615 | 640 | 540 | 330 | ||||

| 26 | 790 | 640 | 650 | 550 | 330 | ||||

| 27 | 791 | 645 | 650 | 550 | 315 | ||||

| 28 | 801 | 610 | 675 | 525 | 330 | ||||

| 29 | 802 | 610 | 700 | 525 | 330 | ||||

| 30 | 803 | 610 | 800 | 535 | 330 | ||||

| 31 | 810 | 620 | 830 | 540 | 330 | ||||

| 32 | 820 | 700 | 520 | 597 | 280 | ||||

| 33 | 910 | 710 | 600 | 610 | 300 | ||||

| 34 | 980 | 715 | 660 | 610 | 300 | ||||

| 35 | 1000 | 715 | 700 | 610 | 300 | ||||

| 36 | 1050 | 715 | 720 | 620 | 300 | ||||

| 37 | 1200 | 715 | 740 | 620 | 300 | ||||

| 38 | 1300 | 715 | 800 | 640 | 440 | ||||

| 39 | 1400 | 745 | 550 | 715 | 440 | ||||

| 40 | 1510 | 740 | 900 | 640 | 360 | ||||

| 41 | 1550 | 775 | 750 | 680 | 330 | ||||

| 42 | 1560 | 775 | 750 | 684 | 320 | ||||

| 43 | 1650 | 775 | 810 | 685 | 440 | ||||

| 44 | 1800 | 780 | 900 | 690 | 440 | ||||

| 45 | 1801 | 790 | 910 | 685 | 400 | ||||

| 46 | 1950 | 830 | 750 | 735 | 440 | ||||

| 47 | 2000 | 875 | 800 | 775 | 440 | ||||

| 48 | 2001 | 870 | 680 | 765 | 440 | ||||

| 49 | 2095 | 830 | 900 | 745 | 440 | ||||

| 50 | 2096 | 880 | 750 | 780 | 440 | ||||

| 51 | 2250 | 880 | 880 | 780 | 440 | ||||

| 52 | 2300 | 880 | 1000 | 790 | 440 | ||||

| 53 | 2700 | 900 | 1150 | 800 | 440 | ||||

| 54 | 3000 | 1030 | 830 | 920 | 500 | ||||

| 55 | 3500 | 1035 | 950 | 925 | 500 | ||||

| 56 | 4000 | 1035 | 1050 | 925 | 500 | ||||

| 57 | 4500 | 1040 | 1200 | 927 | 500 | ||||

| 58 | 5000 | 1040 | 1320 | 930 | 500 | ||||

FAQ

Can you provide OEM services? Yes, we can manufacture products according to your specifications and requirements. Can you arrange delivery through our preferred shipping agent? Yes, we are flexible and can work with your preferred shipping agent for delivery. Do you offer product samples? Yes, we can provide suitable product samples based on your detailed application and requirements. What is your after-sales service policy? We offer a quality guarantee and promise to replace or refund any products with quality issues. Our after-sales service team is available to help resolve any concerns or issues that may arise.When asking for a quotation, please provide the following details

Our Graphite Crucibles’ main raw material is natural flake graphite. They are widely used in nonferrous metals smelting, such as copper, brass, gold, silver, zinc, and lead, as well as their alloys. Our Graphite Crucibles are composed of graphite,clay and silica. They have the advantage of high temperature resistance,good thermal conductivity,strong corrosion resistance and a long service life. In high temperature applications, they have a small coefficient of thermal expansion and can withstand quenching and heating. They also have excellent chemical stability and do not react during the melting process. The inner wall of the graphite crucible is smooth, which prevents leakage and adhesion of molten metal liquid, resulting in good fluidity and casting properties. Graphite crucibles are suitable for casting and molding various types of alloys and are commonly used in smelting alloy tool steel and nonferrous metals.Product Display

Advantages

1.Advanced technology:The molding method used is equal stress high-pressure molding with good isotropy, high density, high strength, uniform compactness, and no defects. 2.Corrosion resistance:The crucible has a temperature range of 400-1600°C, and can be selected according to different ranges. 3.High-temperature resistance:The inorganic non-metallic material used has high purity and does not introduce harmful impurities into the metal melting process. 4.Oxidation resistance:The use of advanced formulas and imported antioxidant materials enhances the antioxidant ability of the refractory material. High temperature stability: SiC has excellent thermal stability and can support high temperatures without deforming or cracking. SiC crucibles can be used at 1600°C temperature,which making them ideal for high-temperature applications. Chemical resistance: SiC is highly resistant to chemical attack by acids and other corrosive substances, which make SiC crucibles suitable for use with a wide range of chemicals, including molten metals,salts, and acids. Excellent thermal shock resistance: SiC has a low thermal expansion coefficient and can resist rapid changes in temperature without cracking. This makes SiC crucibles ideal for applications that involve rapid heating and cooling cycles. Low contamination: SiC is an inert material that does not react with most substances. This means that SiC crucibles do not contaminate the materials being processed, which is essential for materials science research and industrial applications. Long service life: SiC crucibles can last for several years with proper care and maintenance. And they are a cost-effective option compared to other types crucibles. High electrical conductivity: SiC is a semiconductor material with high electrical conductivity, and they are suitable for use in electronic and semiconductor applications.Explanation

1.What is the melted metal’s material? Is it aluminum, copper, or something else? 2.What is the loading capacity per batch? 3.What is the heating mode? Is it electric resistance, natural gas, LPG, or oil? Providing this information will help us give you an accurate quote.